-

E-mail

2801283106@qq.com

-

Phone

15821569256

-

Address

No. 121, Building 2, No. 655 Gaoji Road, Sijing Town, Songjiang District, Shanghai

Shanghai Shirun Industrial Co., Ltd

Shanxi 20kg/m circulating chain code manufacturer

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Shanxi 20kg/m circulating chain code manufacturer

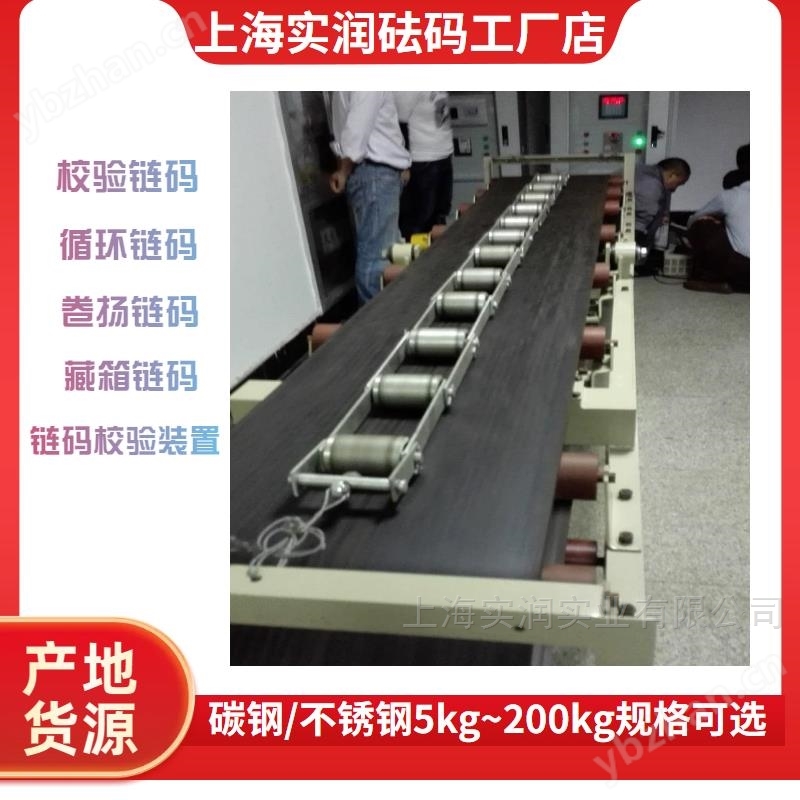

Chain code calibration is a relatively flexible, high-precision, low-cost, easy to operate, and convenient to use calibration method, which belongs to the legal calibration and verification equipment. Ordinary chain codes are easy to use. One chain code can calibrate multiple scales, but it requires on-site assembly and disassembly after calibration, resulting in slightly lower ease of use. In order to solve the inconvenience of use, a chain code retraction device has been applied, which is easy to operate, does not take up space, and can be used to put down the chain code. After calibration, it can be retracted, saving manpower and improving work efficiency.

The chain code hoisting device is widely used in the calibration and verification of electronic belt scales, with high measurement accuracy, long service life, simple operation, and economic benefits. This device is divided into fixed and mobile chain code hoisting devices. Fixed chain code hoisting devices are divided into single roll winches and double roll winches according to the driving single chain code.

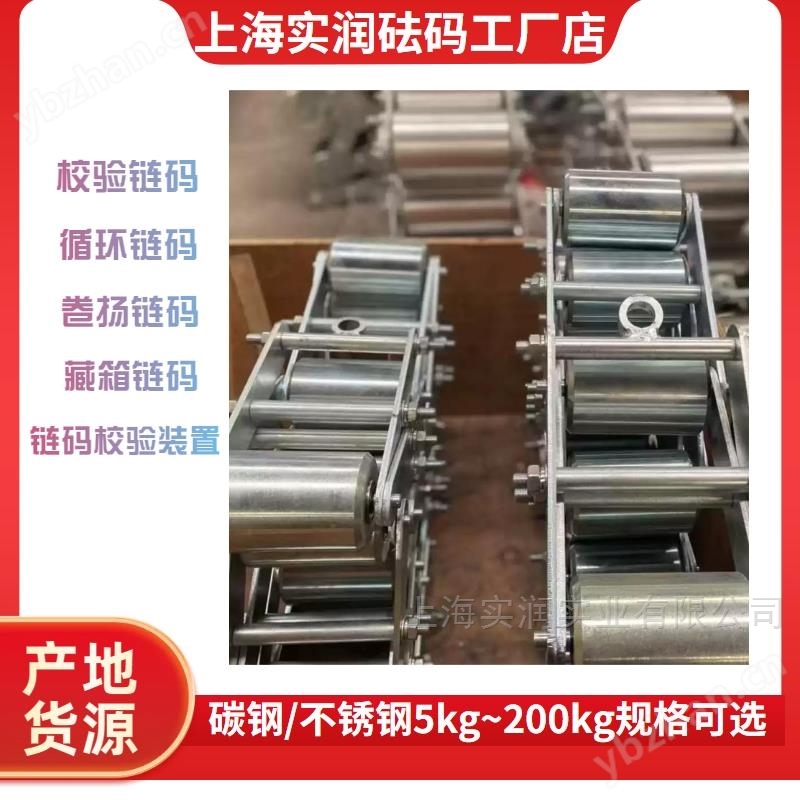

1: Chain code winch device - single roll winch

Only one chain code is used for calibration and calibration, and the entire lifting device consists of a bracket, turntable, chain cable, chain code, etc. The driving motor is driven by a cycloidal pinwheel reducer to drive the drum, which is equipped with a steel wire rope for retracting and releasing chain codes. During calibration verification, place the chain code in the measuring section of the electronic belt scale and simulate physical loads for calibration verification. After calibration, store the chain code in the chain code box until the next use.

2: Chain code winch device - double roll winch

The double roll winch adopts two sets of drums, which can be connected or disconnected separately or simultaneously, and can drive two chain codes separately or simultaneously. A winch can simulate two or three physical quantities, not only measuring the repeatability accuracy of electronic belt scales, but also measuring linear accuracy.

The movable chain code hoisting device consists of a track, a trolley, a bracket, a turntable, a chain cable, a chain code, etc. This device can be used by several parallel conveyor belts. Before calibration, the trolley can move on the track so that the equipment can move freely between the conveyor belts. During the calibration and calibration process, the cycloidal pinwheel planetary reducer is used to place the chain code from the reel on the weighing part of the conveyor belt, simulate physical loads for calibration and calibration, and then drive the reducer to retrieve the chain code from the turntable for storage. It can also be carried by a small car to another belt conveyor to calibrate another electronic belt scale.

3: Selection of Chain Code Hoisting Device

(1) The precision requirement is not very high, and the rated flow rate is large (corresponding to a large calibration chain code quality). When regular calibration is needed, due to the transportation and assembly workload of the chain code, a single roll winch single point calibration is selected. When the belt conveyor is running normally, the chain code is stored in the chain code slot above the conveyor belt. When calibration is required, control the winch to release the chain code from the chain code slot and place it on the belt for calibration.

(2) In high-precision calibration scenarios, multi-point calibration is required, and a double roller lifting device is generally used. When the belt conveyor is running normally, the chain code is stored in the chain code slot above the conveyor belt. When calibration is required, control the crane to release the chain code from the chain code slot and place it on the belt for calibration. This device can calibrate the linear accuracy of the belt scale

Attention to this calibration method: During calibration, the material on the belt should be evenly distributed. Accurately record the average instantaneous flow rate of the display instrument. Cut the material as long as possible. The actual operating speed of the belt should be measured accurately.

The advantages of this calibration method are that although it is a physical calibration, it does not require large measuring and transportation equipment, and there is no problem of material residue. When cutting materials, it is possible to selectively cut uniform materials. Disadvantage: Due to the limited amount of intercepted materials, there is a certain degree of instability in reading the instantaneous quantity of the instrument, so this method has a significant calibration error. The calculation is quite complex and requires accurate measurement of the actual operating speed of the belt.

Shanxi 20kg/m circulating chain code manufacturer