-

Phone

15972987761

-

Address

Building 6, Optics Valley Headquarters, No. 35 Optics Valley Avenue, Wuhan

Product Categories

Wuhan Dongtai Borui Automation Equipment Co., Ltd

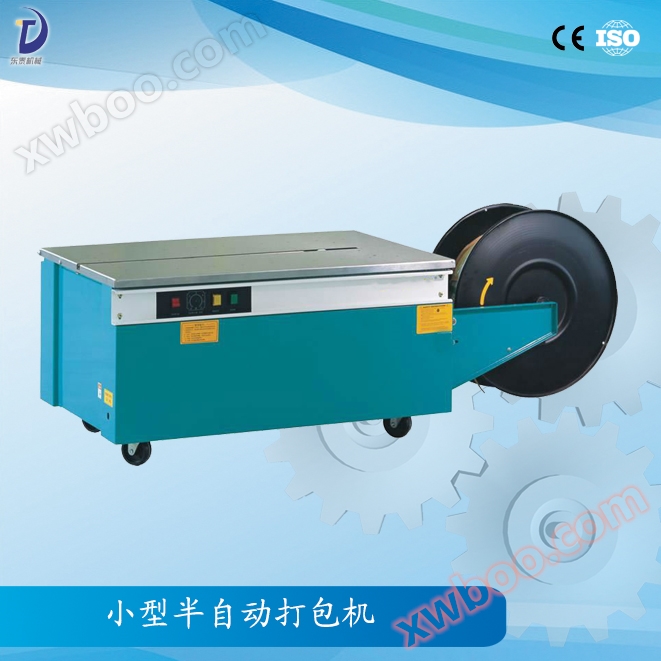

Small semi-automatic strapping machine (strapping machine)

NegotiableUpdate on 12/10

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview

Product Name: Small semi-automatic strapping machine (strapping machine) Product Introduction: The small semi-automatic strapping machine is a new automatic strapping equipment launched by Dongtai Borui Automation, also known as a small strapping machine. The strapping machine has a new operating system, automatic shutdown device, and superior quality

Product Details

Product Name: Small semi-automatic strapping machine (strapping machine)

Application domain:

This small semi-automatic strapping machine is widely used for packaging and bundling cardboard boxes, wooden boxes, wicker boxes, paper packages, and cloth packages in industries such as home appliances, hardware, plastics, electronics, food, medicine, textiles, shopping malls, postal services, and book and magazine distribution. After inserting the PP tape into the machine, the machine can automatically complete the entire bundling process of tightening, bonding, cutting, and removing the tape.

Equipment from different angles:

Power: 250W

Packing speed: 1.5 meters per second

Large bundled items: unlimited

Tightening force range: 6-60KG

PP strip width: 6-15mm

PP tape thickness: 0.5-0.8mm

Machine weight: 55KG

Machine ruler: 1320 * 570 * 450mm

Equipment Details and Accessories Description:

Higher efficiency: Each bundle only takes 1.5 seconds to complete.

Instant heating: It enters the optimal bundling state within 5 seconds after turning on the machine.

Good safety: The rapid heating system has a hot melt design and only has a low voltage of 1V.

Power saving and practical: Equipped with an automatic shutdown device, when the motor stops operating for more than 60 seconds, it will automatically stop and enter standby mode. The bottom is equipped with casters for easy mobility of the device.

Stable operation: Electromagnetic clutch, fast and smooth; Continuous shaft transmission, fast speed, low noise, minimal wear, and low failure rate.

Equipment configuration:

This machine is equipped with a stainless steel panel, a high-quality reducer, 2 support frames (heavy products can be placed on top to resist falling), and the tripod is also welded with support frames.

Equipment comparison:

1. The circuit board and temperature control of the small semi-automatic packaging machine are adjusted separately. The circuit board is horizontal and evenly heated. The circuit board and temperature control of a regular packaging machine are integrated and plug-in. If heated for a long time, the contacts will burn.

2. Some ordinary packaging machines only have one support frame, while this small packaging machine has two support frames with good support strength.

3. The small semi-automatic strapping machine is equipped with a heat sealing speed control function, which can slow down the packaging speed and ensure good heat sealing. Ordinary strapping machines do not have this function.

Equipment packaging effect:

Product Introduction:

The small semi-automatic strapping machine is a new automatic strapping equipment launched by Dongtai Borui Automation, also known as a small strapping machine. The strapping machine has a new operating system and automatic shutdown device, which further enhances its excellent quality. Combined with the double support thickened casing, the load-bearing capacity is stronger. Imported vertical temperature control, equipped with an external knob for adjustable temperature, making operation more convenient and efficient. Newly improved movement with lower malfunctions, one-step hot melt, welding, tightening, and cutting, ensuring more stable quality. This small baler is a machine that uses strapping to wrap products or packaging, then tightens and connects both ends through thermal effect melting or using materials such as buckles. The function of a strapping machine is to ensure that the plastic tape can be tightly attached to the surface of the bundled package, ensuring that the package does not scatter due to loose bundling during transportation and storage, while also bundling neatly and beautifully.Application domain:

This small semi-automatic strapping machine is widely used for packaging and bundling cardboard boxes, wooden boxes, wicker boxes, paper packages, and cloth packages in industries such as home appliances, hardware, plastics, electronics, food, medicine, textiles, shopping malls, postal services, and book and magazine distribution. After inserting the PP tape into the machine, the machine can automatically complete the entire bundling process of tightening, bonding, cutting, and removing the tape.

Equipment from different angles:

Technical Specifications:

Power supply: 220V 50HZPower: 250W

Packing speed: 1.5 meters per second

Large bundled items: unlimited

Tightening force range: 6-60KG

PP strip width: 6-15mm

PP tape thickness: 0.5-0.8mm

Machine weight: 55KG

Machine ruler: 1320 * 570 * 450mm

Equipment Details and Accessories Description:

Equipment features:

Strong adaptability: It can be applied to PP tapes of 6-15mm without the need to replace any parts.Higher efficiency: Each bundle only takes 1.5 seconds to complete.

Instant heating: It enters the optimal bundling state within 5 seconds after turning on the machine.

Good safety: The rapid heating system has a hot melt design and only has a low voltage of 1V.

Power saving and practical: Equipped with an automatic shutdown device, when the motor stops operating for more than 60 seconds, it will automatically stop and enter standby mode. The bottom is equipped with casters for easy mobility of the device.

Stable operation: Electromagnetic clutch, fast and smooth; Continuous shaft transmission, fast speed, low noise, minimal wear, and low failure rate.

Equipment configuration:

This machine is equipped with a stainless steel panel, a high-quality reducer, 2 support frames (heavy products can be placed on top to resist falling), and the tripod is also welded with support frames.

Equipment comparison:

1. The circuit board and temperature control of the small semi-automatic packaging machine are adjusted separately. The circuit board is horizontal and evenly heated. The circuit board and temperature control of a regular packaging machine are integrated and plug-in. If heated for a long time, the contacts will burn.

2. Some ordinary packaging machines only have one support frame, while this small packaging machine has two support frames with good support strength.

3. The small semi-automatic strapping machine is equipped with a heat sealing speed control function, which can slow down the packaging speed and ensure good heat sealing. Ordinary strapping machines do not have this function.

Equipment packaging effect:

Similar Product Recommend