-

E-mail

sunny@chinayxjx.com

-

Phone

136-6249-5431

-

Address

No. 1315-1318, Building 2, Agile Science and Technology Innovation Center, Beitai Road, Taihe Town, Baiyun District, Guangzhou City

- Stainless steel emulsifier

- Cosmetics emulsifier

- Liquid washing production line

- Lotion emulsifying machine

- Stainless steel heating mixing tank

- Homogenizer emulsifier homogenizer

- aerosol filling machine

- Dispersing emulsifier

- Softened PVC water treatment

- Salad dressing emulsifier

- Stainless steel water treatment with mixed bed

- GZJ-Y fully automatic paste filling machine

- Liquid Filling Machine

- Semi-automatic filling machine

- Small filling machine

- Cream production line

- Softened stainless steel water treatment

Guangzhou Yuxiang Light Industry Machinery Equipment Co., Ltd

Stainless steel emulsifier

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Introduction:

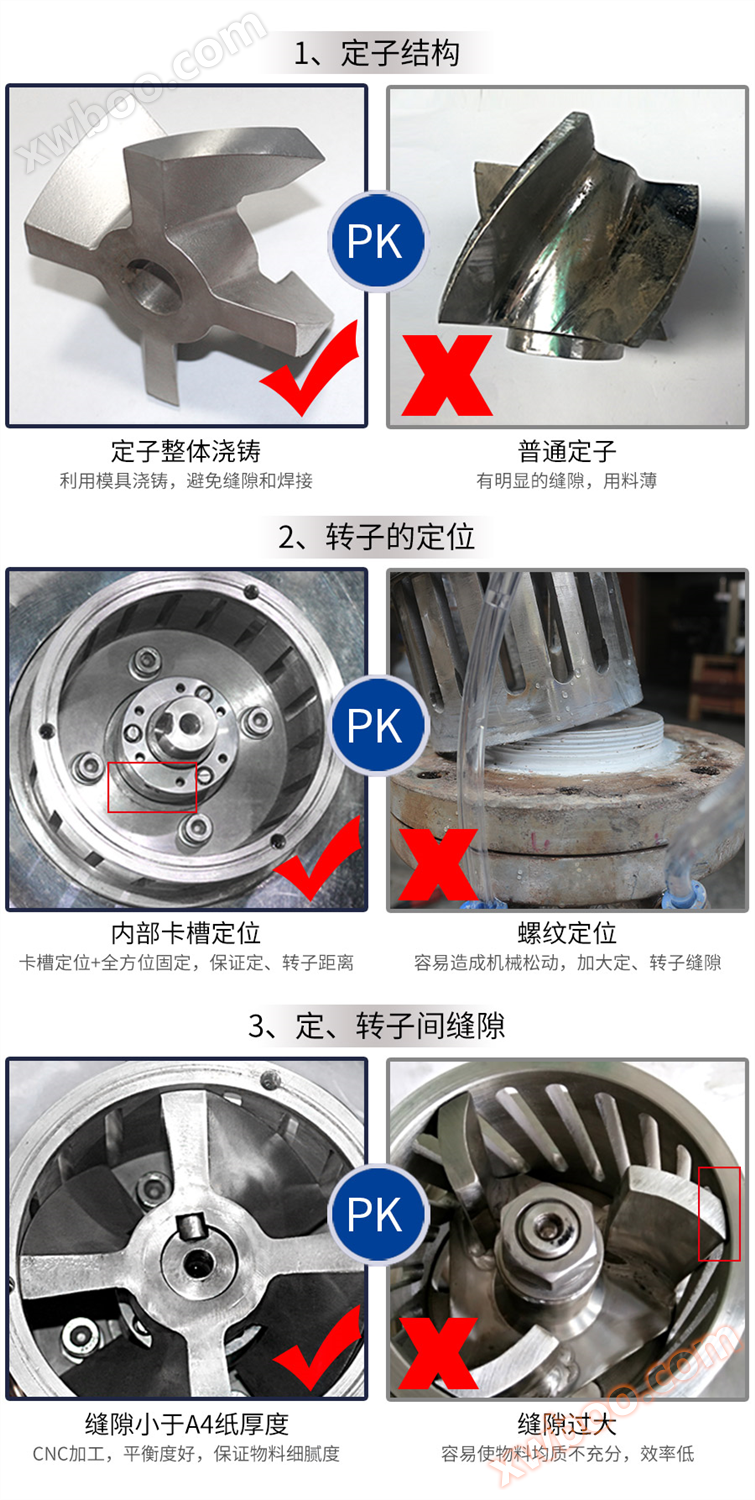

It mainly refers to the rapid and uniform distribution of one or more phases into at least one continuous phase using a high shear emulsifier in a vacuum state, which utilizes the strong kinetic energy brought by machinery to enable the material to withstand hundreds of thousands of liquid shear forces per minute in narrow gaps between the stator and rotor. Through a combination of centrifugal extrusion, impact, tearing, and other comprehensive effects, the emulsion is instantly and uniformly dispersed. After high-frequency cycling, high-quality products with no bubbles, fine texture, and stability are finally obtained.

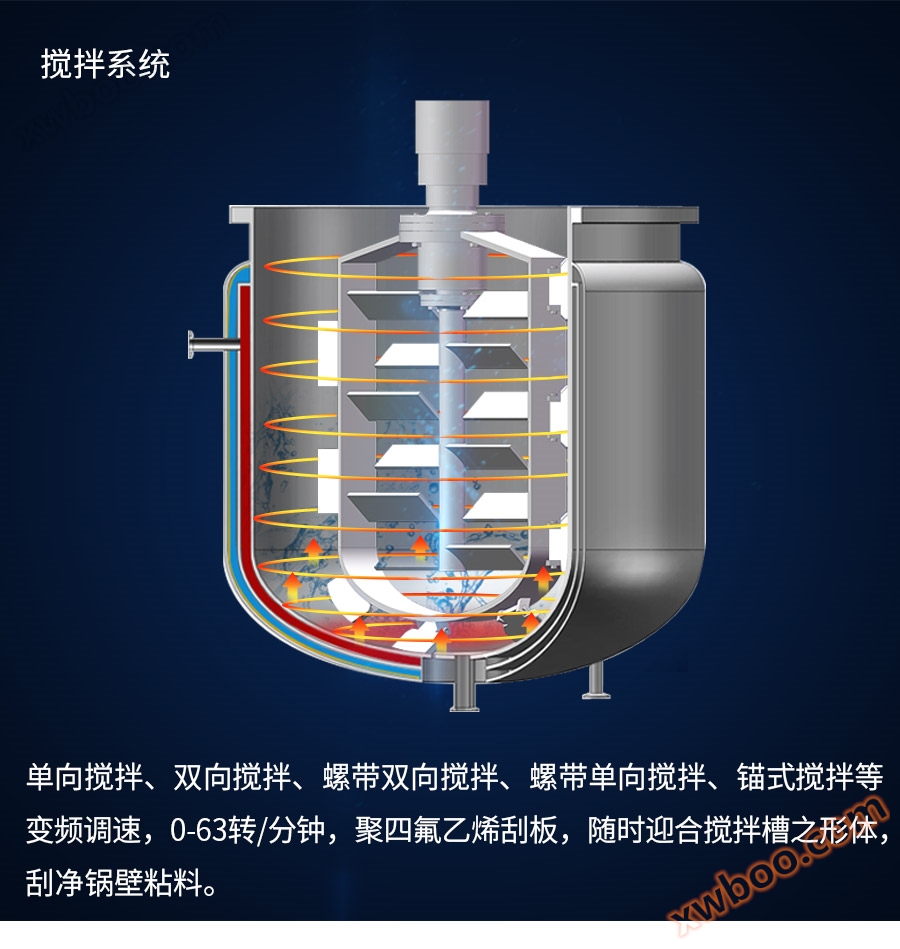

The high shear dispersing emulsifier equipment is a non-standard customized equipment, which is reasonably configured according to the customer's process and suitable for products that require emulsification and stirring in a vacuum state.Can be equipped with low-speed scraping and stirring, used for emulsifying and stirring high viscosity products. Can be configured with a high shear emulsifier, suitable for processes such as dispersion, emulsification, homogenization, and mixing. Can be equipped with: batching system, discharge system, cooling and heating temperature control system, vacuum system, pH online measurement and control, CIP cleaning system, etc.

Application:

Wide application range and strong process controllability.Can be customized to meet hygiene standards, suitable for the production or pilot testing of products in industries such as pharmaceuticals, food, cosmetics, etc. The complete set of equipment is composed of homogenization emulsification main pot, water pot, vacuum system, electric heating or steam heating temperature control system, electrical control, etc. It is a special equipment for producing high-grade cream, medicinal ointment, lotion, etc.

|

Professional design team Professional design team

Yuxiang's professional design team, for youTailored to fit |

|

Efficient service team Efficient service team

Yuxiang's efficient service team,7 * 24 hours24/7 seamless operation |

|

Advanced production equipment Advanced production equipment

Yuxiang's advanced production equipment, excellent factory management, and wealth |

|

Equipment planning and design

According to the customer's production process, factory structure, production capacity, etc., our senior engineers will carry out equipment planning and design

Produce equipment drawings

According to the planning and design, create complete equipment drawings (CAD/3D) and pipeline layouts, which will be confirmed by the purchaser

Verify material and configuration

After placing the order, we will provide detailed production drawings and conduct a record review of the production equipment. During production, we will invite customers to participate in production supervision, verify materials and configurations

Conduct comprehensive acceptance

After production is completed, arrange quality inspection for comprehensive acceptance, and have detailed acceptance data for reference (including image data);

Debugging, installation, and training

After the equipment enters the buyer's factory, we will dispatch professional engineers to conduct on-site debugging, installation, and training

National Consultation Hotline:020-3667-0808

Manager Sun: 136-6249-5431

QQ:2850788655

E-mail: sunny@chinayxjx.com

Address: Agile Science and Technology Innovation Center, Beitai Road, Taihe Town, Baiyun District, Guangzhou City

Building 2, No. 1315-1318