-

E-mail

46014616@qq.com

-

Phone

18028963555

-

Address

1st Floor, No. 3 Shugang Avenue, Hongmei Town, Dongguan City, Guangdong Province

Dongguan Dexiang Instrument Co., Ltd

Stainless steel inner pot electric blast drying oven

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Stainless steel inner pot electric blast drying ovenIt is a common laboratory and industrial equipment widely used in fields such as material drying, heat treatment, and experimental sample preparation. Its core features lie in the material of the inner liner, heating method, and design of the air circulation system, which together determine the performance and applicable scenarios of the equipment.

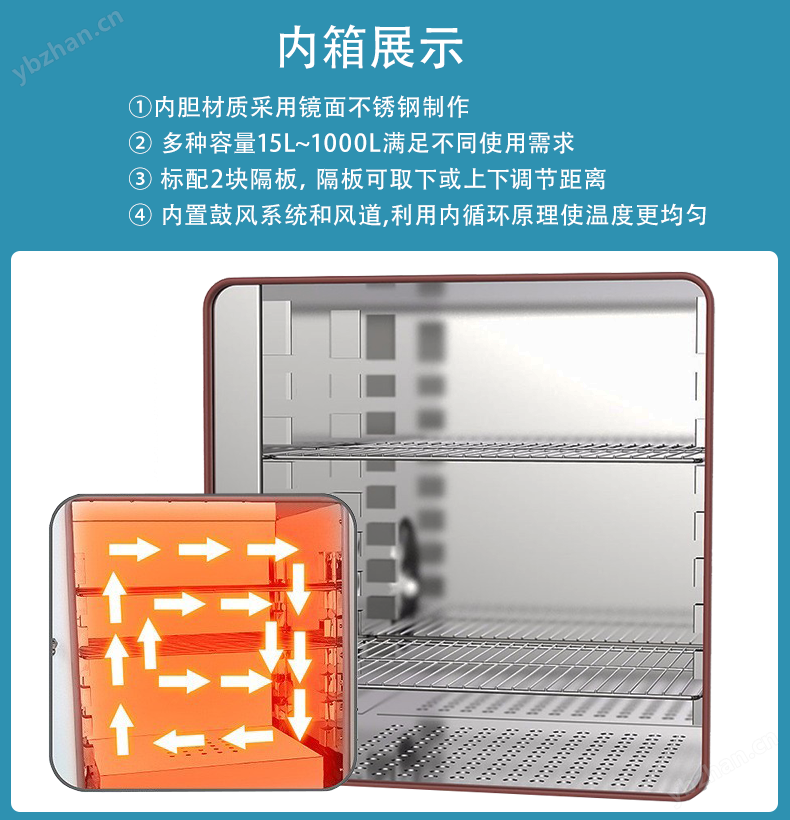

Structure and Working Principle

The device mainly consists of a box, a heating system, an air circulation system, and a control system. The inner liner is made of stainless steel material, which has good corrosion resistance and easy cleaning, suitable for environments with high cleanliness requirements. Heating systems are usually achieved through electric heating elements, and heat is driven by fans to form a uniformly distributed airflow inside the box, ensuring temperature consistency.

A common issue is:Why choose stainless steel as the inner liner material?

Stainless steel can resist the erosion of various chemicals and is not easily oxidized or releases harmful substances in high temperature environments. In addition, the smooth surface is easy to clean and avoids residual pollutants, making it suitable for industries with high hygiene requirements such as medicine and food.

Technical Features

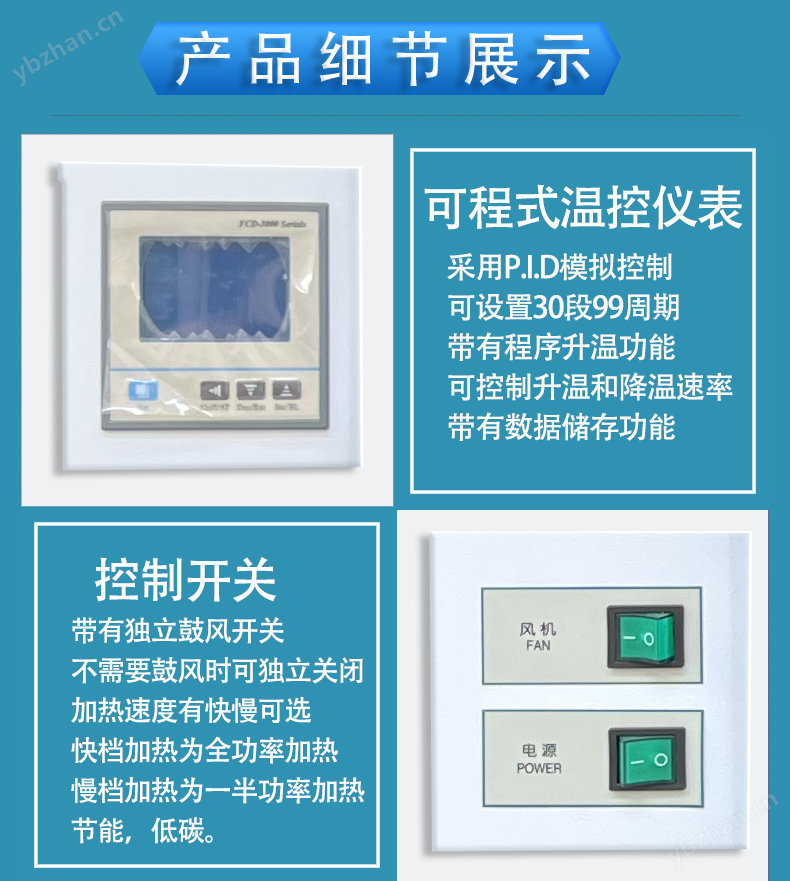

temperature uniformity

By using a forced convection system, the temperature distribution inside the box is relatively uniform. This is crucial for processes that require stable heating, such as drying electronic components or pre-treatment of reagents.temperature control accuracy

Using a digital control system, users can set and maintain a specific temperature range. The temperature control accuracy can usually meet most experimental and production needs.Application flexibility

According to different needs, the air volume and temperature parameters can be adjusted to adapt to diverse material processing.

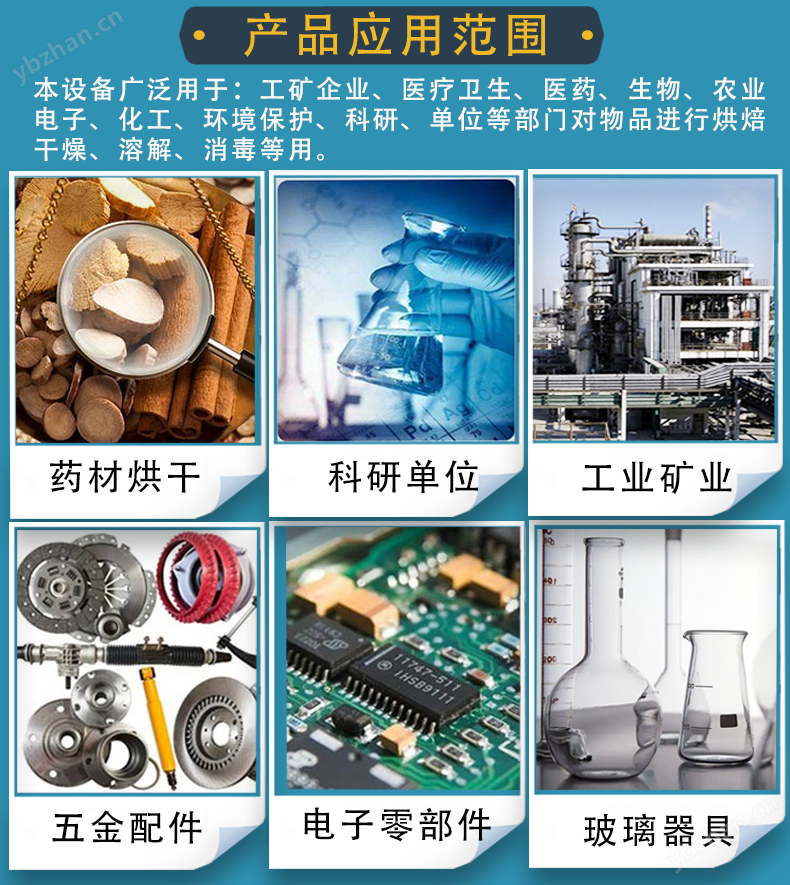

The following is a brief summary of common application scenarios:

| Application field | specific purpose |

|---|---|

| laboratory research | Drying glassware, heat treating experimental samples, removing material moisture |

| electronics industry | Pre treatment of circuit boards and drying of components to prevent performance degradation caused by moisture |

| Medicine and Food | Drying of equipment and handling of packaging materials to avoid contamination and microbial growth |

| Chemical and Materials | Powder drying and catalyst activation enhance material stability |

Common problems in use

How to ensure the long-term stable operation of the drying oven?

Regular cleaning of the inner container and air duct, as well as checking the status of heating elements and fans, are necessary maintenance measures. In addition, avoiding overloading or prolonged continuous operation can extend the lifespan of the equipment.

What materials are not suitable for processing in such equipment?

Substances that are flammable, explosive, or release toxic gases should be avoided from being placed. Meanwhile, materials that are extremely sensitive to humidity may require a combination of other drying methods.

summary

Stainless steel inner pot electric blast drying ovenWith its stable performance and wide range of applications, it has become a fundamental device in multiple industries. Understanding its working principle and applicable scenarios can help users complete related tasks more efficiently and safely. In the process of selection and use, combining actual needs and paying attention to maintenance can further leverage its technological advantages.