-

E-mail

13803026441@126.com

-

Phone

13803026441

-

Address

No. 8, Haitai Development Road 5, Huayuan Industrial Zone, Binhai High tech Zone, Tianjin

Tianjin Zhiyi Times Technology Development Co., Ltd

Steel ultra-low emission integrated platform

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Steel ultra-low emission integrated platform

Product Introduction

The Zhiyi era ultra-low emission control and governance integration platform, relying on the ultra-low emission policies of key industries such as steel, coking and cement, and the Ministry of Ecological Environment's emergency emission reduction rating policy for heavy polluted weather, has built a set of environmental protection control and governance platform integrating "organized emissions+unorganized emissions+clean transportation" by virtue of the powerful three-dimensional modeling capability, combined with cutting-edge technologies such as digital twins, online monitoring, visual AI, big data Internet of Things, and intelligent linkage. This platform not only has the function of data collection and analysis, real-time monitoring and data collection to help enterprises make scientific decisions, but also can intelligently adjust the parameters of governance equipment based on data and prediction results, and implement precise governance measures. At the same time, the platform supports remote monitoring and management, allowing enterprises to use the Internet or Efficient management of mobile APP.

2. Product Capability

Source supervision: Comprehensive coverage of organized and unorganized emission supervision

Intelligent Perception: Achieving Intelligent Monitoring and Fine Control of Factory Environment

Process control: Real time tracking of the operational status of governance and production facilities

Effect control: Monitoring of air quality near dust production points and roads

Integrated management: integrating comprehensive display, collaborative control, and command and dispatch

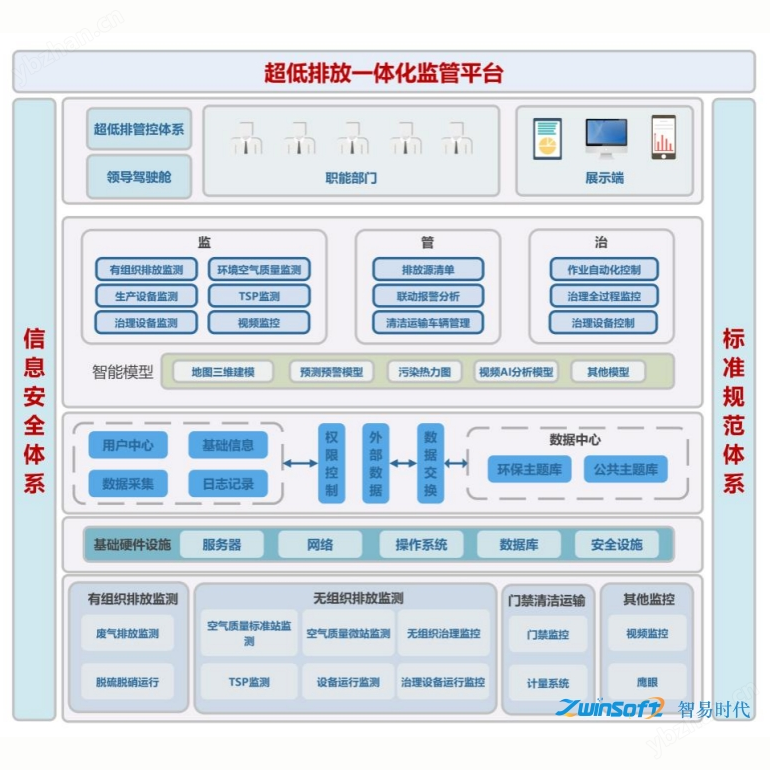

3. System Architecture Diagram

IV. Feature Highlights

Integrated supervision of the entire production line: global supervision of the entire production line to improve the systematic and collaborative nature of environmental management.

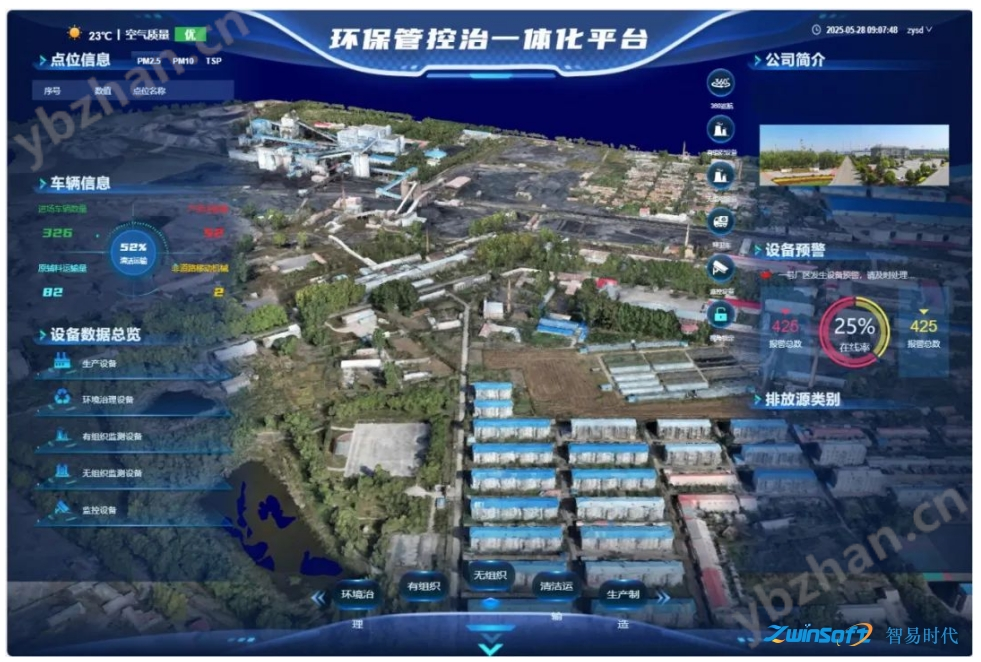

Global management perspective: Using 3D modeling technology to construct a 3D model of the factory area, digitizing and visualizing environmental business data to provide managers with a comprehensive visual management perspective.

Comprehensive source supervision: Comprehensive monitoring of organized and unorganized pollution emissions to ensure effective control of pollution sources.

Real time process control: Real time tracking of the working status and operational effectiveness of governance and production facilities to ensure effective implementation of environmental protection measures.

Efficient and effective control: Online monitoring of organized and unorganized pollution data, timely reporting and coordinated governance, improving the response speed and effectiveness of pollution control.

Data intelligent analysis: relying on monitoring data, intelligently analyze environmental pollution trends and equipment performance, automatically generate logs and reports, and improve facility efficiency.

Transportation ledger management: supports access control systems and metering systems to seamlessly integrate into the clean transportation system, achieving electronic and intelligent management of vehicle entry and exit as well as cleaning.

Wu|Steel ultra-low emission integrated platformProject Case

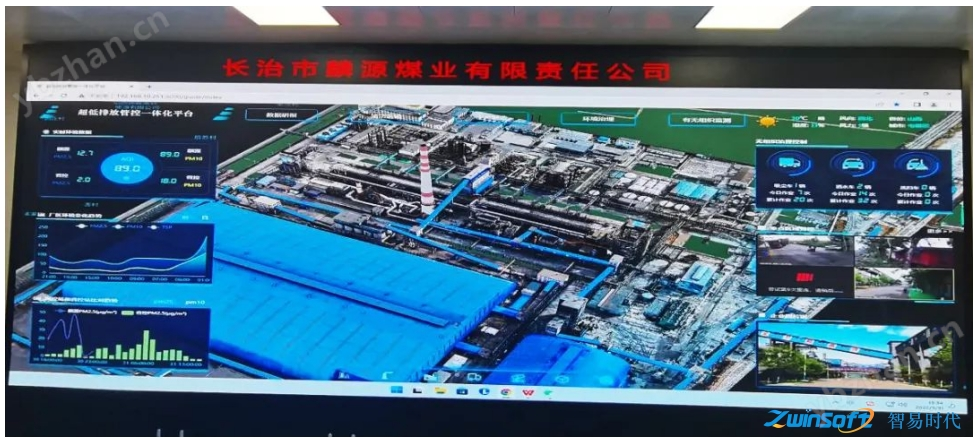

01 Iron and Steel Plant Ultra Low Emission Control and Governance Integrated Platform Project

Carry out environmental protection work around the entire factory, systematically manage the organized, unorganized, source list, clean and exhausted contents of the group, and establish an emission source list. Realize the informatization, dataization, and intelligence of pollutant emission control throughout the factory. Reduce environmental risks and hazards within the group, enhance the group's ability to prevent and control sudden environmental accidents, and conduct a comprehensive evaluation of the entire group to promote its green development.

02 Steel Plant Eagle Eye Intelligent Dust Reduction Identification and Control System Project

Based on the actual situation of the enterprise, design Eagle Eye recognition linked ultra-fine environmental dust suppression equipment to enable dust particles and water mist particles to adsorb, condense, and settle with each other, thereby achieving the goal of suppressing dust pollution. Effectively control dust from the source. At the same time, the eagle eye recognition and control system of the material shed will be connected to the enterprise's ultra-low emission integrated platform to achieve remote control of start and stop, which meets the requirements of ultra-low emission for material yard control.

03 Luzhong Cement Ultra low Emission Control and Treatment Integrated Platform Project

Taking into account the actual situation and needs of cement enterprises, a customized ultra-low emission control and treatment integrated service plan has been developed, and professional technical support and training services have been provided. By deploying ultra-low emission control and treatment integrated platforms, pollutant monitoring equipment, video surveillance and other facilities, real-time monitoring and precise treatment of pollutants in the production process and material storage have been achieved. The smooth implementation of the project ensured a significant reduction in the pollutant emissions level of the cement enterprise.

04 Dafeng Coking Ultra Low Emission Control and Treatment Integrated Platform Project

Through the four core functional scenarios of intelligent monitoring, precise governance, intelligent control, and AI intelligent operation, and the comprehensive application of 3D GIS, visualization, Internet of Things, artificial intelligence and machine vision, big data, and cloud computing technologies, the ultra-low emission 3D visualization intelligent control platform has helped Dafeng Coking to win the recognition of provincial-level high-tech enterprises, green factories, and the honorary title of "outstanding enterprise leading the industry".

05 Linyuan Coal Industry Ultra Low Emission Control and Management Integrated Platform Project

By integrating advanced information technology, Internet of Things technology, and big data analysis, a comprehensive environmental monitoring and management platform is constructed. The platform is capable of real-time monitoring of pollutant emissions during the production process, automatically adjusting control equipment to ensure that emission standards meet national ultra-low emission requirements. At the same time, the platform also has data analysis and decision support functions to help fuel processing enterprises optimize production processes, reduce energy consumption, and improve energy utilization efficiency.

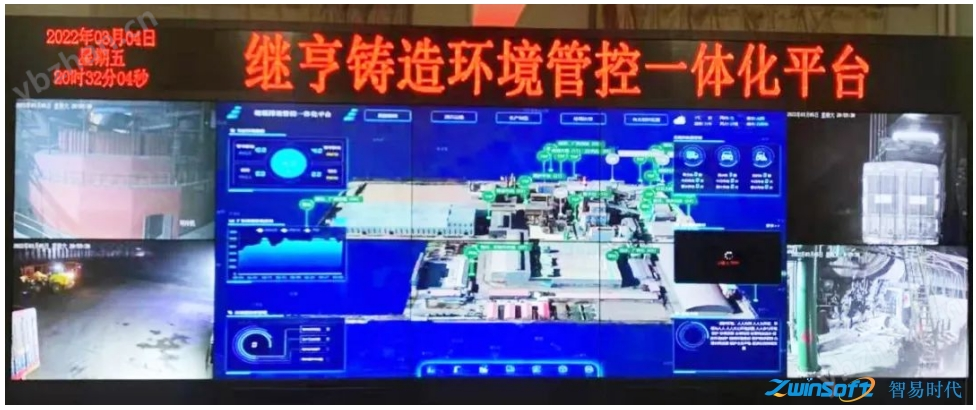

06 Jiheng Casting Industry Ultra Low Emission Control and Governance Integrated Platform Project

By integrating emission monitoring, data analysis, pollution source control, linkage governance, environmental management and other functions, real-time monitoring and precise management of the entire casting production process have been achieved. The platform can automatically detect and adjust the emission indicators during the production process, ensuring that all pollutant emissions meet ultra-low standards. Meanwhile, by optimizing the production process through data analysis, Jiheng Foundry has significantly improved energy utilization efficiency and reduced production costs.