-

E-mail

sales@chotest.com

-

Phone

18928463988

-

Address

No. 1001, Xili Xueyuan Avenue, Nanshan District, Shenzhen, China

Shenzhen Zhongtu Instrument Co., Ltd

Surface roughness detection profilometer brand

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

SJ5800Surface roughness detection profilometer brand0.1nm ultra-high precision! Improve precision measurement efficiency by over 50%.

Are you facing these pain points in precision machining industries such as bearings, mechanical manufacturing, and molds: complex surfaces require multiple measurements, low efficiency in batch testing, large measurement errors leading to product rework, and high operational barriers increasing labor costs? SJ5800Surface roughness detection profilometer brandWith the core advantages of ultra-high precision, efficient intelligence, and full field adaptation, it has become the precision measurement choice for enterprises through real data and industry cases.

1、 Core advantages

1. High precision guarantee: error ≤ ± 1 μ m, meeting strict testing standards

(1) Precision hard indicators: 0.1nm resolution (minimum contour resolution of 0.001 μ m), system residual ≤ 3nm, repeatability 1 δ ≤ 1nm, standard ball measurement error ≤± 1 μ m (R ≤ 10mm), angle measurement accuracy ≤± 1 ′, in compliance with international standards such as GB/T, ISO, JIS, etc.

(2) Stable core configuration: Ultra high straightness grinding grade friction guide rail (straightness ≤ 0.2 μ m/100mm)+special ruby shaft, matched with precision calibration table to automatically compensate for measuring needle wear, ensuring long-term measurement accuracy consistency.

2. Efficient and intelligent: Batch measurement efficiency increased by 50%, with zero threshold for operation

(1) Integrated measurement saves time: contour, roughness, and waviness can be scanned in one go without switching modules. The measurement steps for complex workpieces are reduced by 80%, and the detection time for a single workpiece is compressed from 15 minutes to 5 minutes.

(2) Batch measurement is more convenient: CNC fixed coordinate system mode+template setting, simple workpiece one click measurement, complex workpiece segmented measurement can be reused in batches, a certain mechanical parts factory batch detects the contour of the screw, and daily inspection measurement is increased from 200 pieces to 500 pieces.

(3) Zero threshold operation: One click insertion and extraction of measuring needles (no need to lock screws), quick positioning with a combination handle, intuitive software interface, and independent operation within 1 hour of novice training; Dual protection of hardware and software reduces probe damage rate by 90%.

3. Full scene adaptation: compatible with both soft and hard workpieces, covering the needs of multiple industries

(1) Wide adaptability range: adjustable constant force of 0.5-3mN, compatible with various types of workpieces such as metal and soft materials; 12-24mm wide range roughness measurement (Ra0.012 μ m~12.5 μ m), supporting detection of complex shapes such as circular arcs, spherical surfaces, and irregular surfaces.

(2) Exclusive customization solution: Optional bearing specific fixtures (maximum measurable inner diameter of Φ 300mm), roller analysis module, used by a certain automotive parts enterprise to detect blade surface Ra parameters and meet the requirements of precision mold cavity contour measurement.

2、 Core functions

1. Integrated evaluation of geometric quantities and positional tolerances: supports measurement of 20+geometric quantities such as points, lines, circles, angles, distances, etc., and automatically evaluates 7 major positional tolerances such as straightness, roundness, and contour.

2. Efficient and convenient data management: Supports contour comparison in CNC, XML, and DXF formats, automatically generates Word/PDF/Excel/SPC analysis reports, and can export statistics in bulk (including key indicators such as CPK and PPK).

3. Intelligent assistance function: automatically finding inflection points, deleting outlier points, analyzing multiple record splicing, customizing color management annotation features, and improving data processing efficiency.

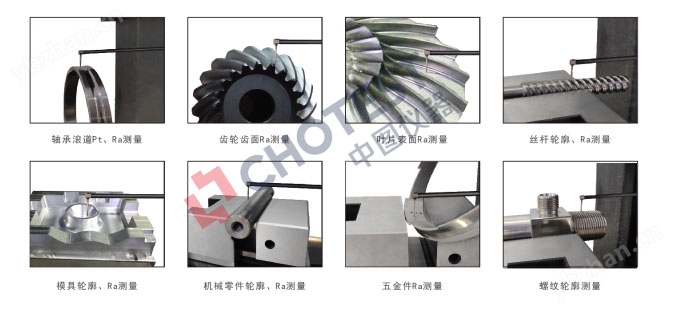

3、 Typical applications

4、 Core configuration

1. 1 host+dual diamond measuring needle (standard), combined adjustment control handle, dedicated calibrator (standard measuring block+G10 grade silicon carbide ball)

2. Universal worktable (three-axis adjustment), marble worktable (load-bearing 500kg), branded computer+HP laser printer

3. Measurement software (including SPC analysis, Q-DAS file output)+

Whether you are a bearing enterprise that needs batch testing of roller convexity or a mechanical processing factory that needs to improve the measurement efficiency of complex parts, SJ5800 can provide precise and adaptable solutions. Click to consult and obtain industry exclusive measurement solutions and prototype trial qualifications for free, allowing data to witness the dual leap of measurement accuracy and efficiency!

(Note: The product parameters are based on the SJ5800-100/200 model, and roller analysis modules, oversized workbenches, and other configurations can be selected according to needs. New parameters are subject to consultation replies.)