-

E-mail

770800751@qq.com

-

Phone

13918558055,15358831790

-

Address

Building 23, No. 4703 Jiaotong Road, Putuo District, Shanghai

- IC card recharge and payment quantitative control system

- Multi channel ingredient filling quantitative control system

- Dust liquid mixing/dispensing control system

- Two way ingredient filling quantitative control system

- Multi station liquid level control cabinet

- Liquid level quantitative control device (liquid level control device)

- Liquid level high and low control equipment

- Liquid level control cabinet

- Liquid level control equipment

- Intelligent single light injection measurement and control instrument control cabinet

- Double Two Channel Material Distribution Quantitative Control System

- Hydrochloric acid quantitative control system

- Quantitative control system for oxygen

- Explosion proof dual pump multi station material distribution and quantitative control system mobile cart

- PLC touch screen dual pump multi station material distribution and quantitative control system mobile cart

- Mobile Explosion proof Quantitative Control System Filling Car - Shanghai Longkui/LK

- Multi station material distribution and quantitative control system for ordinary double pump, mobile cart

- Diesel Integrated Turbine Flow Meter Shanghai

- Anti corrosion integrated electromagnetic flowmeter Shanghai

- Boiler steam V-cone flowmeter Shanghai

- Sea water remote transmission electromagnetic flowmeter Shanghai

- Firefighter held ultrasonic flowmeter Shanghai

- Hydraulic oil small caliber turbine flowmeter Shanghai

- Formaldehyde Split Vortex Flow Meter Shanghai

- Potassium hydroxide remote transmission electromagnetic flowmeter Shanghai

- Medical water remote transmission metal tube float flowmeter

- LUGB type vortex flowmeter for air conditioning water in Shanghai

- Diesel TDS Ultrasonic Flow Meter Shanghai

- Biogas remote transmission V-cone flowmeter Shanghai

- TDS ultrasonic flowmeter for domestic sewage in Shanghai

- Ultrasonic flowmeter for measuring alcohol in Shanghai

- Shanghai LKJ type ethanol metal tube float flowmeter

- Formaldehyde metal tube float flowmeter LKJ type

- Compressed air metal tube float flowmeter LKJ type

- Chemical raw material metal tube float flowmeter Shanghai

- Distilled water metal tube float flowmeter Shanghai

- TDS type ultrasonic flowmeter for air conditioning water

- Shanghai TDS type liquid ultrasonic flowmeter

- Room temperature gas V-cone flowmeter LKV type

- Bring back the zero elliptical gear flowmeter

Shanghai Longkui Industrial Technology Co., Ltd

TDS ultrasonic flowmeter for domestic sewage in Shanghai

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Product Details

Selection of flow meters for flow measurement:

The selection of flow meters refers to the comprehensive consideration of the safety, accuracy, and economy of measurement based on production requirements and the actual situation of instrument product supply. The flow sampling device and measuring instrument, as well as the form and specifications of the measuring instrument, are determined according to the properties and flow conditions of the measured fluid.

The safety and reliability of flow measurement first depend on the reliability of the measurement method, that is, the sampling device will not cause accidents due to mechanical strength or electrical circuit failures during operation; Secondly, the measuring instruments will not affect the safety of the production system under normal production or fault conditions.

On the basis of ensuring the safe operation of instruments, we strive to improve their accuracy and energy efficiency. For this purpose, it is not only necessary to select display instruments that meet accuracy requirements, but also to choose a reasonable measurement method based on the characteristics of the measured medium. For the measurement of the main steam flow rate in power plants, mature standard throttling and differential pressure flow meters are generally used due to their importance for the safety and economy of the power plant. The wastewater and fuel from chemical water treatment belong to dirty flow and low Reynolds number viscous flow, respectively, and are not suitable for standard throttling components. For measuring high-quality pipelines, it is recommended to use non-contact and non pipe breaking external clamp ultrasonic flow meters. For dirty flow, non-standard throttling devices such as circular orifice plates with differential pressure gauges or ultrasonic Doppler flow meters are generally used. For viscous flow, volumetric, target, or wedge flow meters can be used respectively. The inlet water volume of the turbine, the circulating water volume of the condenser, and the reheated steam of the reheater unit are all flow measurement parameters with large pipe diameters (above 400mm). Due to difficulties in processing and high pressure loss, standard throttling devices are generally not used. According to the characteristics of the measured medium and the requirements for measurement accuracy, insert flow meters, speed measuring components with differential pressure gauges, ultrasonic flow meters, or non-destructive methods such as marking and simulation methods are used to measure flow. For more information, please visit

In order to ensure the service life and accuracy of the flowmeter, attention should also be paid to the anti vibration requirements of the instrument when selecting. In humid and hot areas, it is necessary to choose a humid and hot instrument. The correct selection of instrument specifications is also an important part of ensuring the service life and accuracy of the instrument, and special attention should be paid to the selection of static pressure and temperature resistance. The static pressure (i.e. pressure resistance) of the instrument should be slightly greater than the working pressure of the measured medium, usually 1.25 times, to ensure that no leakage or accidents occur. The selection of measuring range mainly involves the selection of the upper limit of the instrument scale. Choosing too small can cause overload and damage to the instrument panel; Choosing too large may affect the accuracy of the measurement. Generally, it is selected as 1.2-1.3 times the maximum flow value in actual operation. Contact instruments installed on production pipelines for long-term operation should also consider the energy loss caused by flow measurement components. In general, multiple measuring elements with high pressure loss, such as throttling elements, should not be used in the same production pipeline.

There are two particularly important measurement techniques in farmland irrigation:

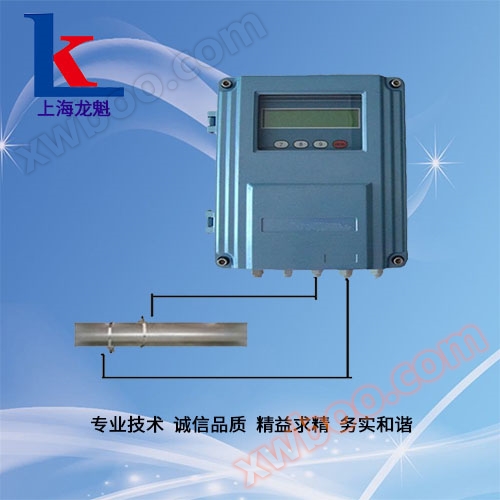

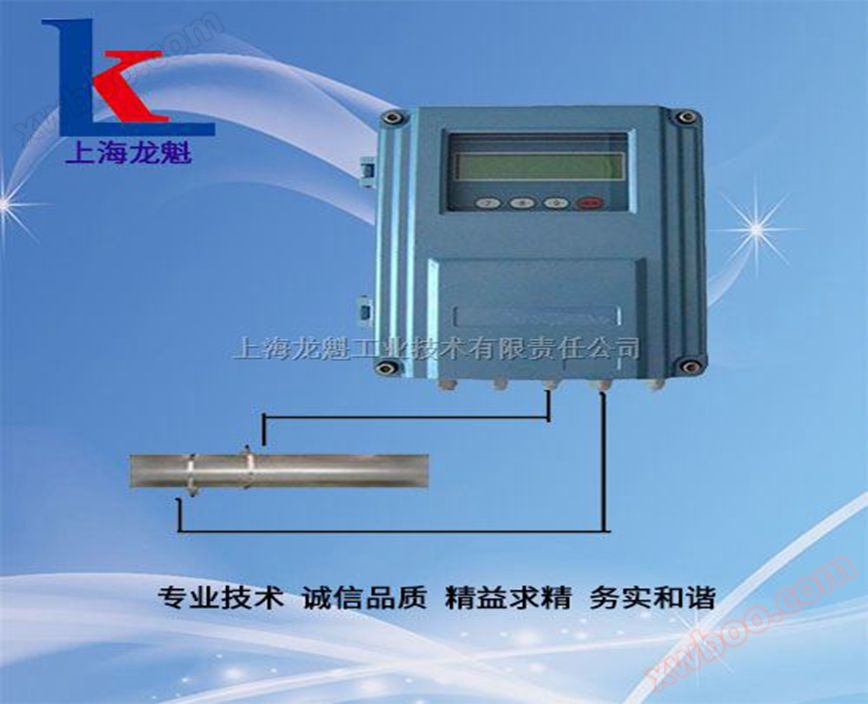

There are two techniques to pay special attention to when measuring flow using the velocity area method: one is the use of ultrasonic flow meters, which are classified by installation methods into external clamp ultrasonic flow meters, insertion ultrasonic flow meters, and pipeline ultrasonic flow meters. The other is the use of electromagnetic flow meters, of course, there are also many varieties, such as pipeline type and insertion type, which will not be repeated. Readers can refer to relevant materials for further understanding.

Ultrasonic technology calculates flow velocity by measuring the propagation time of ultrasonic waves across a channel. The transmitter and receiver are placed on both sides of the channel, so that the angle between the wave path and the direction of water flow is within the range of 45 ° to 60 °. This geometric relationship creates a time difference between sound pulses in the upstream and downstream directions. The shape of the channel determines whether a single path system or a multi-path system will be used, that is, one or several transmit receive pairs will be used.

The electromagnetic technology for measuring current is to use a magnetic field artificially established in a conductive water flow, and then measure the composite potential difference across both sides of the water flow. The electromagnetic flowmeter is mainly composed of a water channel, an excitation coil, and a pair of electrodes.