Temperature and humidity environment of temperature control box, high and low temperature cycle, cold and hot shock box, high temperature simulation: can be set and stably output high temperature environment according to needs (common range -20 ℃~150 ℃, -40 ℃~180 ℃, etc., depending on the model), simulating the state of the product during high temperature storage and operation. Low temperature simulation: capable of creating low-temperature environments as low as -70 ℃, -100 ℃, or even lower, to assess the performance stability of products at low temperatures (such as low-temperature starting of electronic components, low-temperature brittleness of rubber, etc.). $r $n high and low temperature cycle: supports setting cycle programs such as "high temperature → low temperature → high temperature" to simulate the product's temperature alternating cycle

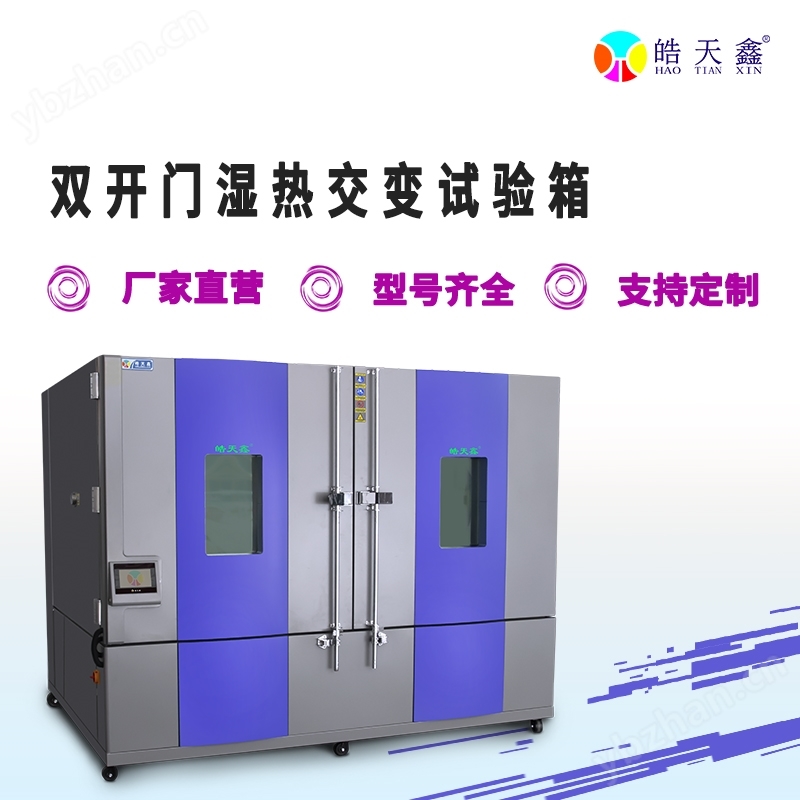

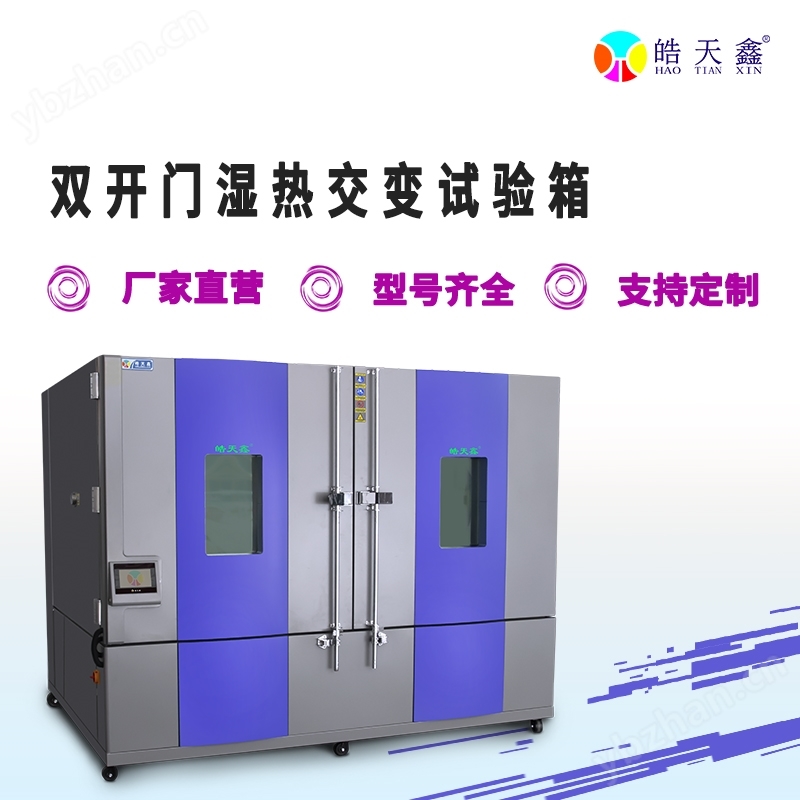

Temperature control box, temperature and humidity environment, high and low temperature cycling, cold and hot shock box

Timer function: Set the total duration of the test, and automatically stop the machine after the time is up, without the need for manual monitoring.

Program editing: The model supports multi-stage program editing (such as "25 ℃ constant temperature for 2 hours → heating up to 80 ℃ constant temperature for 4 hours → cooling down to -40 ℃ constant temperature for 6 hours → cycling 3 times"), automatically executing complex test procedures.

Data recording and export: Equipped with a built-in data logger, it stores temperature data during the test process. Some support USB flash drive export, printer printing, or uploading to a computer through communication interfaces (RS485, Ethernet) for easy preparation of test reports.

Temperature control box, temperature and humidity environment, high and low temperature cycling, cold and hot shock box

By simulating temperature and humidity environments (such as high temperature and high humidity, low temperature and low humidity cycles), the aging process of products can be accelerated, and the environmental adaptability of products in long-term use can be quickly evaluated to predict potential failures in advance.

For example, testing rubber and plastic parts to observe whether they crack, deform, age, or become brittle under high, low, and high humidity conditions; Paint testing to verify its adhesion and corrosion resistance under different temperature and humidity conditions.

Temperature setting and display: The target temperature can be manually or automatically set, and the current temperature can be displayed in real time through the panel (digital tube/LCD screen) to intuitively grasp the temperature status.

Heating/cooling control: Based on the difference between the set temperature and the actual temperature, the heating (such as heating tube, PTC) or cooling (such as compressor cooling, semiconductor cooling) module is automatically activated to maintain temperature stability.

Temperature regulation accuracy control: By using algorithms such as PID regulation, temperature fluctuations are reduced (accuracy can reach ± 0.1 ℃~± 1 ℃, depending on the model), avoiding temperature fluctuations.

Accurate temperature setting and display: Set the target temperature through the touch screen or buttons, display the current temperature and set temperature in real time, and some support precision display to one decimal place (such as 25.5 ℃).

Constant temperature control: using PID and other adjustment algorithms to reduce temperature fluctuations (accuracy can usually reach ± 0.5 ℃~± 2 ℃), ensuring that the temperature remains stable at the set value during the experiment.

Heating/cooling rate control: The speed of temperature change can be adjusted (such as 5 ℃/min, 10 ℃/min) to meet the requirements of different standards (such as IEC, GB) for test rate.

Timed control: Temperature control start and stop times can be set to achieve "timed startup and shutdown" without the need for manual monitoring (such as laboratory timed constant temperature and industrial equipment timed preheating).

Multi stage program temperature control: Some models support setting multiple temperature curves (such as "maintain 25 ℃ for 2 hours → heat up to 80 ℃ for 3 hours → cool down to 40 ℃ for 1 hour"), automatically executing complex temperature control processes.

Data recording and communication: It can store historical temperature data (some with USB export function), support RS485 and other communication interfaces, connect with PLC and computer, realize remote monitoring and centralized control.

Overtemperature protection: When the temperature inside the box exceeds the set safe upper/lower limit, an audible and visual alarm will be immediately triggered, and the heating/cooling power supply will be cut off to prevent damage to the sample and equipment.

System fault protection: including sensor faults (wire breakage, poor contact), abnormal refrigeration system pressure, heater overload, etc., automatic shutdown alarm in case of faults, indicating the type of fault.

Sample protection: Some models are equipped with independent temperature limiters, which can set the safe temperature of the sample separately, ensuring that the sample is not damaged.