-

E-mail

2860308992@qq.com

-

Phone

13011285763

-

Address

Room 1066, Building 2, East Ring Road, Yanqing Park, Zhongguancun, Yanqing District, Beijing

Beijing Zhongke Micro Nano Precision Instrument Co., Ltd

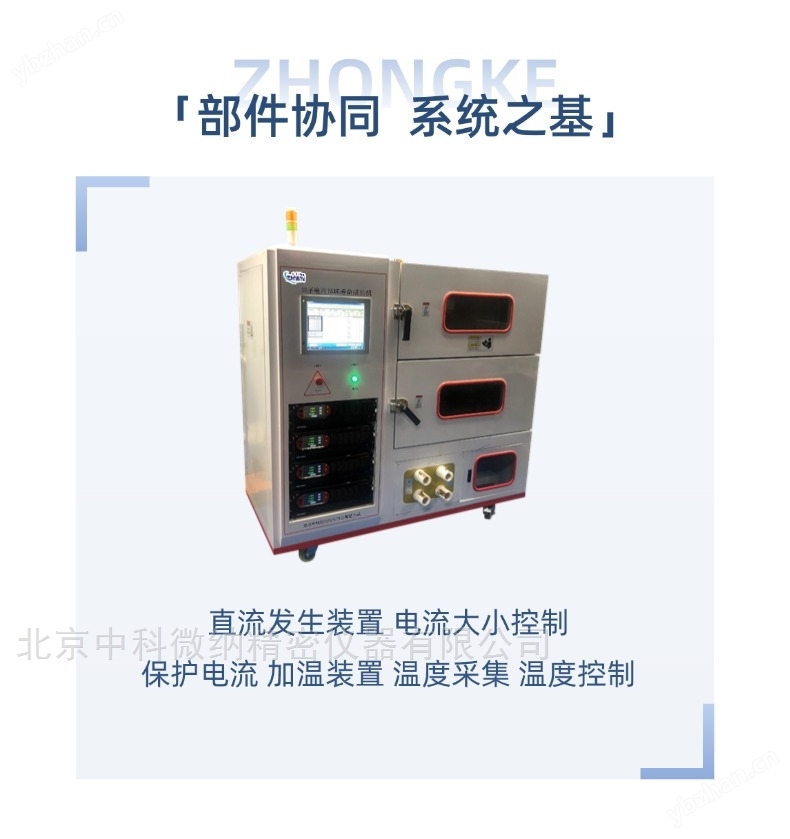

Terminal current cycle life test system

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Terminal current cycle life test system

DLSM-800

Equipment Overview:

Terminal current cycle life test system-This instrument is mainly used for testing the current cycle life of cable terminals. Its main working principle is to maintain a constant high temperature environment at the line temperature, and complete the test by cyclically loading and disconnecting the rated working current for a certain cycle period.

Application fields:

Suitable for life testing and evaluation of civil, aerospace, and cable terminals

Product advantages:

1. Equipped with 4 imported DC power supplies with a current of 800A

2. Each DC power supply is independently tested for continuity without affecting other tests

3. Heating room temperature range: Room temperature 250 ° C

4. Can be tested at room temperature or high temperature

5. Support long-term operation without time constraints

6. The experimental temperature can be freely set

7. The on/off time of each channel can be freely set

8. Real time display of temperature and current curves

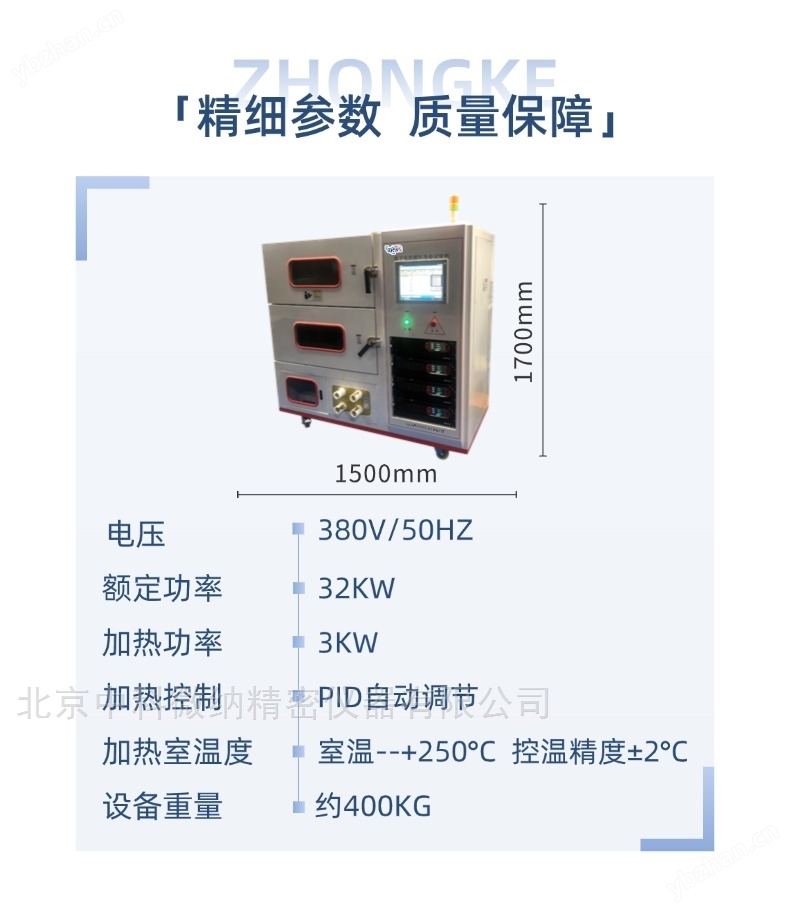

Technical Specifications:

1. 4-channel power supply, maximum current per channel 800A

2. Number of heating chambers 2

3. Heating chamber temperature: room temperature -+250 ° C, temperature control accuracy ± 2 ° C

4. Heating power: 3KW

5. Heating control: PID automatic adjustment

6. Real time display of temperature curve during the trial process, recording the current and temperature corresponding to each test at each time point, and being able to save test data

7. The software can set the connection time, disconnection time, and number of cycles for each test

8. Temperature control method: Cable surface temperature sensor and internal temperature control of the test box (optional);

9. Temperature sensor: PT100, two channels with temperature control box, two temperature sensors per channel, sensors are point type. Sensor A collects the temperature inside the box, while sensor B collects the temperature of the test piece. The wiring length should meet the requirement of arranging the B sensor at any position inside the box;

10. The temperature control box is distributed in two layers, with internal dimensions of each layer: left and right length of 960 millimeters, up and down height of 400 millimeters, and front and rear depth of 400 millimeters.

11. Rated power: 32KW

12. Voltage: 380V/50HZ

13. Equipment dimensions: length 1500mm * width 900mm * height 1700mm

14. Equipment weight: approximately 400KG