-

E-mail

51037070@qq.com

-

Phone

18028963555

-

Address

Room 113, Building 1, No. 3 Shugang Avenue, Hongmei Town, Dongguan City, Guangdong Province

Guangdong Derui Testing Equipment Co., Ltd

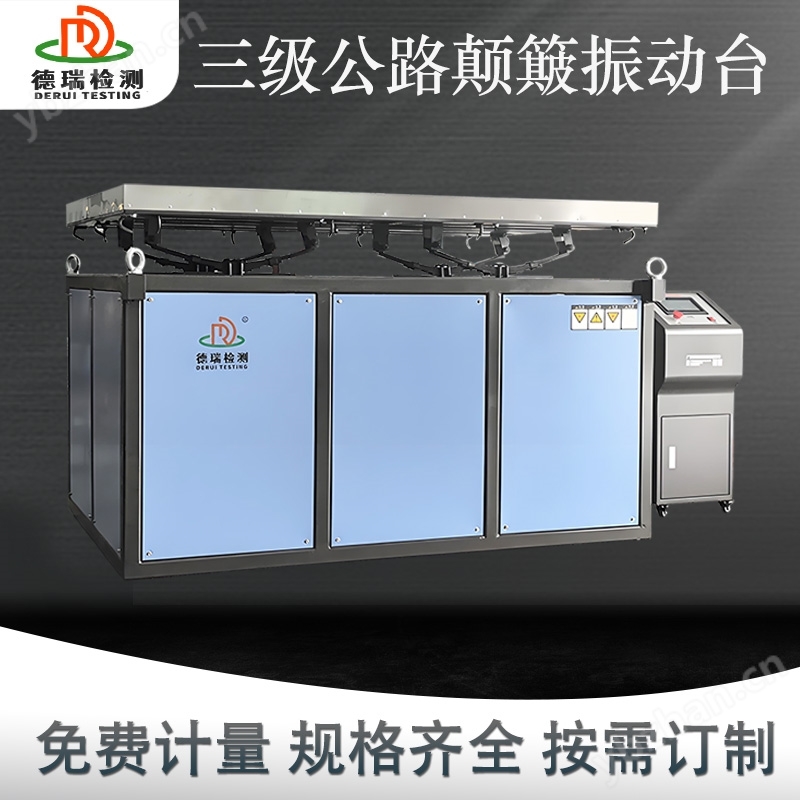

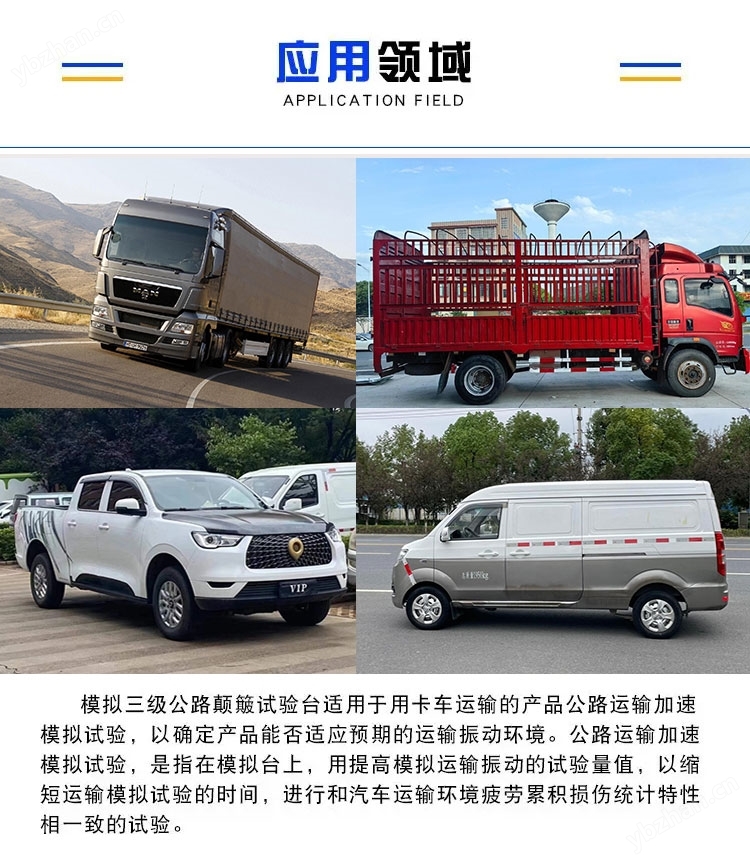

Third-class highway bump tester Logistics packaging cushioning performance test

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

As a manufacturer, we provide you withThird-class highway bump tester Logistics packaging cushioning performance testSolution.

1、 The core purpose of the test is to quantitatively evaluate the protective effect of buffer materials

The core of buffering performance testing isScientifically measureCushioning materials in packaging (such as EPS foam, EPE pearl cotton, air cushion film, paper tray, etc.) in simulated transportation environmentAbsorb energy, reduce impact, and disperse vibrationThe ability.

The ultimate goal is to answer a question:Can the current packaging solution reduce the impact and vibration transmitted to the product below the safety threshold in the predetermined logistics environment

2、 How does our testing device accomplish this task?

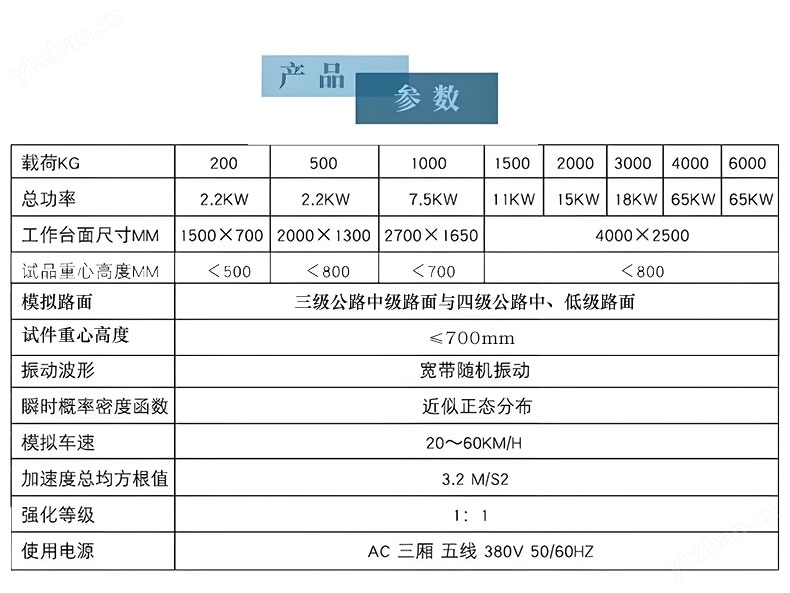

The equipment provides you with quantitative test results by accurately simulating the vibration environment of third-class highway and combining data monitoring.

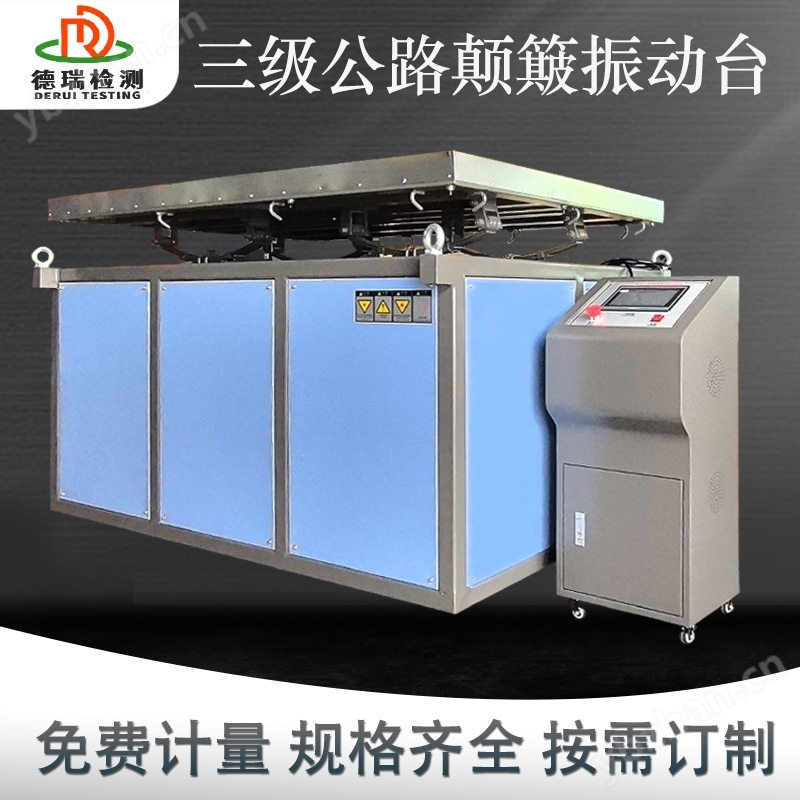

Accurate environmental simulation:

Equipment can generateVertical vibrationSimulate the up and down movement of a vehicle on bumpy roads.

by settingLow frequency large amplitude(Simulating potholes) andMedium to high frequency and amplitude(Simulate continuous gravel road) and other modes, fully covering the vibration characteristics of third-class highway.

Monitoring and comparison of key data(This is the key to evaluating buffering performance):

Compare the product received in two testsAcceleration (G-value).

Excellent cushioning materialIt will significantly reduce the G value transmitted to the product.The more the G value decreases, the better the buffering performance.

By analyzing the data, it is possible to accurately determine whether the buffer material is suitable, whether the thickness needs to be adjusted, and whether the structure needs to be optimized.

the first time: Willbare metalFix the product on the table without any packaging and run the testing program. Record the vibration response that the product itself can withstand (usually measuring the acceleration of its critical parts).

the second time: WillPackaged productsFix it on the table using the buffer material to be evaluated, and thenSame testing conditionsRun the program.

test methodUsually, two comparative tests are required:

performance evaluation:

Efficient testing process:

Devices are usually built-inISTA、ASTM、GB/T 4857Wait for the vibration testing program in the standard (such as ISTA 1A, 2A, 3A), call it with one click, and quickly start the test.

Automatically generate a report after testing, clearly displaying vibration curves and key data for analysis and decision-making.

3、 The core value that testing brings to you

Scientific selection of materialsSpeak with data to help you select effective and cost-effective buffering materials from a variety of options.

Optimized DesignAccurately determine whether the current packaging is "excessive" or "insufficient", in order to optimize the structure and amount of cushioning materials, and achievecost reduction and efficiency improvement.

Reduce damage rateDiscovering problems before actual transportation significantly reduces cargo damage and customer complaints caused by improper packaging.

Enhance customer trustPresent professional testing reports to clients to demonstrate your emphasis on cargo safety and enhance cooperation confidence.

4Third-class highway bump tester Logistics packaging cushioning performance testTypical testing process

Prepare samplesPrepare a product in perfect condition and a complete packaging for testing.

Install sensors(If precise measurement is required): Fix the accelerometer inside the product or at a critical location.

Set up the programSelect the corresponding transportation testing standard (such as ISTA 3A).

execute testsStart the device and complete the vibration test for the specified time.

Result Analysis:

Check the packagingCheck whether the outer box and inner lining are crushed, cracked, or deformed.

inspect the productCheck if the product's functionality and structure are intact.

analyze dataQuantitatively evaluate buffering performance by comparing data such as G-values.

Next cooperation suggestion

In order to provide you with suitableBuffer performance testing planPlease provide the following information:

test subjectWhy do you primarily conduct product testing? (such as small electronic products, home appliances, precision instruments, etc.)

cushioning materialWhat buffering materials are currently being used or considered for use?

Test StandardAre there any specific testing standards that need to be followed?

budget rangeIt is convenient for us to recommend cost-effective models for you.

We are not only equipment suppliers, but also your partners for packaging optimization. Our equipment can provide you with the key data needed for scientific decision-making, helping you find the best balance between cost and protection effectiveness. Welcome to contact us anytime for detailed technical information and solutions!