-

E-mail

Tzzrc1992@163.com

-

Phone

18226662876

-

Address

Tianchang Economic Development Zone, Anhui Province

Anhui Tianzhun Instrument Co., Ltd

Tianzhun 80G high-frequency radar level gauge

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Introduction

Tianzhun 80G high-frequency radar level gaugeExtremely short microwave pulses with low emission energy are transmitted and received through an antenna system. Radar waves travel at the speed of light. The running time can be converted into level signals through electronic components. A special time extension method can ensure stable and accurate measurements in a very short period of time.

Even in complex working conditions, if there are false echoes, use a new oneMicroprocessing technologyDebugging software can also accurately analyze the echo of the material level.

input

The antenna receives reflected microwave pulses and transmits them to the electronic circuit. The microprocessor processes this signal and identifies the echoes generated by the micro pulses on the surface of the material. The correct recognition of echo signals is completed by intelligent software, with an accuracy of up to millimeter level. Distance from the surface of the materialDTime travel with pulseTDirectly proportional:

D=C×T/2

among whichCFor the speed of light

Due to the distance of the empty tankEIf known, then the material levelLFor:

L=E-D

output

By inputting the height of the empty tankE(=Zero point), full tank heightF(=Set the instrument to full range and some application parameters, which will automatically adapt the instrument to the measurement environment. correspond to4-20mAOutput.

Application medium

Tianzhun 80G high-frequency radar level gaugeSuitable for non-contact continuous measurement of liquid, slurry, and granular material levels, suitable for large temperature and pressure changes; In situations where inert gases and volatiles are present.

The measurement method adopts microwave pulses and can operate normally within the industrial frequency range. The beam energy is low and can be installed in various metal and non-metal containers or pipelines, without causing harm to the human body and the environment.

measurement method

It is based on the principle of time domain reflection(TDR)Based on the radar level gauge, some of the pulses of the radar level gauge are reflected to form echoes and return along the same path. However, considering the effects of corrosion and adhesion, the final value of the measurement range should be at least away from the endpoint of the antenna100mmFor overflow protection, a radar level gauge safety distance can be defined and attached to the blind spot. The minimum measurement range is related to the antenna. With different concentrations, foam can both absorb microwave and reflect it, but it can be measured under certain conditions. Return to the pulse transmission device.

Measuring principle

Radar level gauge is based on the principle of time-domain reflection(TDR)Based on the radar level gauge, the electromagnetic pulse of the radar level gauge propagates along the steel cable or probe at the speed of light. When it encounters the surface of the measured medium, some of the pulses of the radar level gauge are reflected to form echoes and return to the pulse emitting device along the same path. The distance between the emitting device and the surface of the measured medium is proportional to the propagation time of the pulse between them. The liquid level height is calculated by .

Installation Instructions

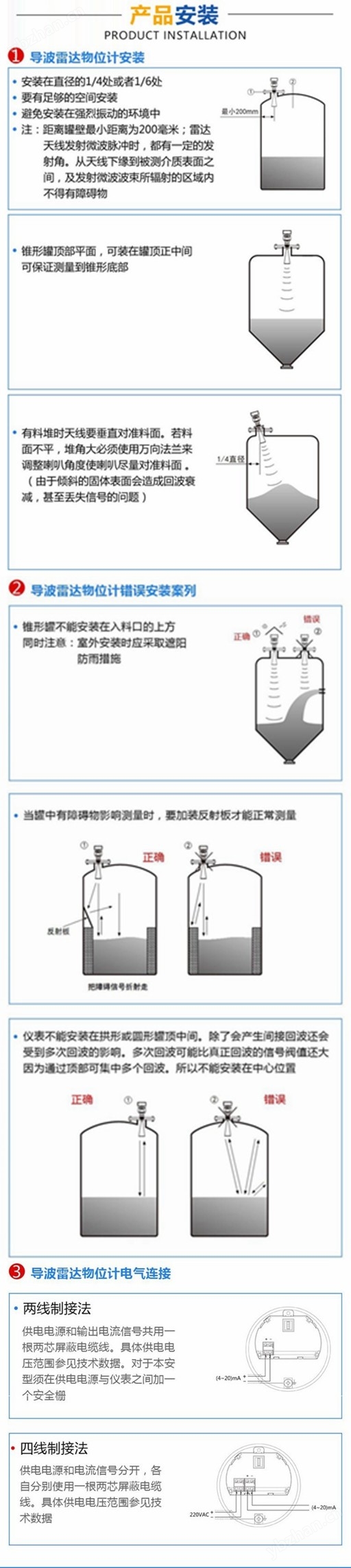

(1)From the wall to the outer wall where the short pipe is installed: the distance from the tank wall is the diameter of the tank1/6The minimum distance is200mm.

(2)Cannot be installed above the feeding port.

(3)Cannot be installed in the center position. If installed in the center, multiple false echoes will be generated, and interference echoes will cause signal loss.

(4)The diameter of the takeover should be less than or equal to the length of the shielding tube(100mmor250mm).

Precautions

1.The measurement range starts from the point where the beam touches the bottom of the tank, but in special cases, if the tank bottom is concave or conical, measurement cannot be carried out when the level is below this point.

2.If the medium has a low dielectric constant and the bottom of the tank is visible when it is at a low liquid level, it is recommended to set the zero point at a low height to ensure measurement accuracyCThe location.

3.In theory, it is possible to measure the position reaching the antenna end, but considering the effects of corrosion and adhesion, the final value of the measurement range should be at least away from the antenna end100mm.

4.For overflow protection, a safe distance can be defined to be added to the blind spot.

5.The minimum measurement range is related to the antenna .

Advantages and Applications

1.Radar level gauges can measure liquid and solid media such as crude oil, slurry, raw coal, pulverized coal, volatile liquids, etc;

2.It can be measured in vacuum and can measure all dielectric constants>1.2The medium has a measurement range of up to70m;

3.The power supply and output signal are transmitted through a two core cable (loop circuit),adopt4…20mAOutput or digital signal output;

4.Non contact measurement installation is convenient, using extremely stable materials that are sturdy and durable, accurate and reliable, with a resolution of up to1mm;

5.Not affected by working conditions such as noise, steam, dust, vacuum, etc;

6.Not affected by changes in medium density and temperature, the process pressure can reach400bar,The medium temperature can reach-200℃to800℃;

7.There are multiple installation methods to choose from: top installation, side installation, bypass pipe installation, waveguide pipe installation;

8.Debugging can be done in multiple ways: using programming modules for debugging (equivalent to an analysis and processing instrument)SOFTSoftware debuggingHARTHandheld programmer debugging, easy and fast to debug .

Key selection points

The correct selection of radar level gauge is necessary to ensure its better use. The selection of which type of radar level gauge to use should be determined based on the physical and chemical properties of the measured fluid medium?Adjust the diameter, flow range, lining material, electrode material, and output current of the radar level gauge?Can adapt to the properties of the measured fluid and the requirements of flow measurement.

1Precision functional inspection

The accuracy level and function of the instrument are selected based on measurement requirements and usage scenarios to achieve cost-effectiveness. For example, in situations such as trade settlement, product handover, and energy measurement, a higher level of accuracy should be chosen, such as1.0Level0.5Grade, or higher;For process control applications, choose different accuracy levels according to control requirements;In some cases where only the process flow rate needs to be detected without precise control and measurement, a slightly lower accuracy level can be chosen, such as1.5Level2.5Grade, even 4.0At this point, a low-cost plug-in radar level gauge can be selected.

2Measurable medium

When measuring medium flow rate, instrument range, and caliber, the full-scale flow rate of a radar level gauge can be used to measure medium flow rate0.5—12m/sThe selection within the scope is relatively wide. Select instrument specifications(caliber)Not necessarily the same as the process pipeline, it should be determined based on whether the measured flow range is within the flow rate range. That is, when the flow rate of the pipeline is too low to meet the requirements of the flow instrument or the measurement accuracy cannot be guaranteed at this flow rate, the instrument diameter needs to be reduced to increase the flow rate inside the pipeline and obtain satisfactory measurement results.

Maintenance of radar level gauge

Radar level gauges are mainly composed of electronic components and antennas, with no movable parts. They rarely encounter malfunctions during use. Occasionally, some volatile organic compounds in the storage tank may crystallize on the horn mouth or antenna of the radar level gauge. Regular inspection and cleaning are sufficient, and maintenance is minimal.

In daily maintenance, it can be usedPCBy remotely observing the reflection wave curve of the machine, the liquid level gauge can be used to identify false waves that may arise later, eliminate the influence of these interference reflection waves, and ensure accurate measurement.