-

E-mail

Tzzrc1992@163.com

-

Phone

18226662876

-

Address

Tianchang Economic Development Zone, Anhui Province

Anhui Tianzhun Instrument Co., Ltd

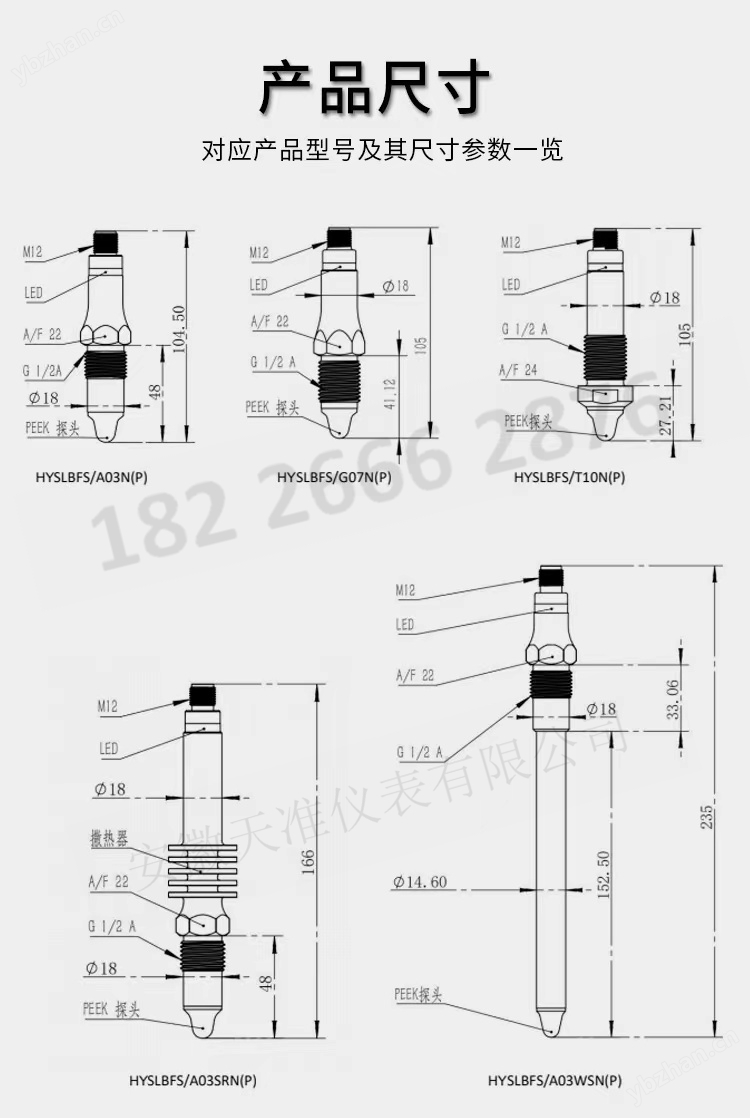

Tianzhun capacitive microwave level switch

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

working principle

Tianzhun capacitive microwave level switchThe probe and internal electronic unit form a high-frequency resonant circuit. A high-frequency microwave electric field is formed near the probe.

When the probe is covered by a medium or the dielectric constant of the medium changes, the resonant frequency will undergo a significant change, and the internal electronic unit will pass through

Compare the current resonant frequency with the user set alarm value, and output or turn off the alarm signal. This measurement method can effectively eliminate

The influence of conductive adhesive hanging materials

Characteristics and application scenarios

wide applicability |

Suitable for dielectric constant ≥1.5 Solid and liquid |

2 Road independent alarm |

It can detect layered media, such as beer and foam, oil and water. |

Anti hanging material properties |

Multiple probe structures effectively detect adhesive conductive slurries |

compact structure |

Suitable for small space equipment integration |

wetted materialPEEKAnd stainless steel |

Suitable for hygiene and industrial settings |

easy to use |

Can set alarm points and view measurement values on site |

Data upload |

provide 1 road24VUnidirectional upload of serial data. |

Application restrictions

1. Tianzhun capacitive microwave level switchNot suitable for rough media (such as quartz sand) and heavy block materials.

2. Not suitable for media that are corrosive to the probe and liquid receiving parts (such as ozonated water)

3. The probe cannot be exposed to ultraviolet radiation

storage and transportation

Storage conditions:

Storage temperature:-40~85℃

Use original packaging

Transport to measurement point:

Transport the equipment to the measuring point in its original packaging

Installation location

Measurement equipment can be installed at any position in containers, pipelines, or tanks. The measuring equipment can be adjusted using a socket wrench

Installed at difficult to operate measurement points.

The level switch can be installed at any part of the container.

1 Upper limit of material level

2 Lower limit of material level

3 Dry operation protection

Installation in non sanitary environments

Risk of injury caused by hazardous media

►Wear protective equipment against hazardous media such as various acids, alkaline solutions, etc.

►Empty containers and pipelines before installation.

direct installation

The specific steps are as follows:

1. Before and during installation, ensure that there is no medium inside the container and pipeline.

2. Must be usedPTFEWrap the tape (raw tape) around the thread of the level switch.

3. Use a wrench(22AF)Rotate the level switch into the installation hole(G1/2).

4. Tightening torque30Nm

Installation using stainless steel process connectors

Attention: When using stainless steel process connectors, sealing gaskets or the tapered surface of the connector can be used for sealing

do not usePTFEAdhesive tape (raw tape).

The specific steps are as follows:

1. Before and during installation, ensure that there is no medium inside the container and pipeline.

2. Turn the level switch into the process connector

3. Tightening torque15~20Nm

Using plastic (such asPTFE)Process connector installation

Attention: When using plastic process connectors, sealing gaskets or conical seals can be used instead of using themPTFE

Adhesive tape (raw tape).

The specific steps are as follows:

1. Before and during installation, ensure that there is no medium inside the container and pipeline.

2. Determine whether to use based on the sealing performance of the process connectorPTFE(Teflon) adhesive tape.

3. Turn the level switch into the process connector

4. Tightening torque15~20Nm

5. Grounding treatment: metal shell of material level switch and metal tank wall(Frame Ground)Between them, it should be done through wires or

Connect with metal clips.

volume

Installation in hygienic environments

Risk of injury caused by hazardous media

►Only welded sleeves (stainless steel) can be used for installation in sanitary environments

►Cannot be used in sanitary environmentsPTFESeal with adhesive tape or other elastic material.

►Welding work must be completed by welders who have received training in the field of hygiene.

Installation of welding sleeve

The specific steps are as follows:

1. Before and during installation, ensure that there is no medium inside the container and pipeline.

2. Weld in sleeves or adapters should be installed in a hygienic manner and flush internally.

3. Polish the weld seam toRa < 0.8Mm.

4. The leakage port points downwards.

5. Tighten the material level switch

6. Tightening torque15-20Nm

Check after installation

►Is the equipment intact and undamaged(visual inspection)?

►Have sufficient protective measures been taken to prevent the equipment from being directly exposed to sunlight and rain?

►Is the equipment properly secured?

Check after connection

►Whether the equipment or cables are intact and undamaged(visual inspection)?

►Does the cable meet the requirements?

►Has the cable been stress relieved?

►Is the power supply voltage consistent with the nameplate parameters?

►Is the connector plug tightened?