-

E-mail

2623729929@qq.com

-

Phone

13871140023

-

Address

Baishazhou Fenghuo Steel Market in Hongshan District, Wuhan City

Wuhan GeTe Electromechanical Equipment Co., Ltd

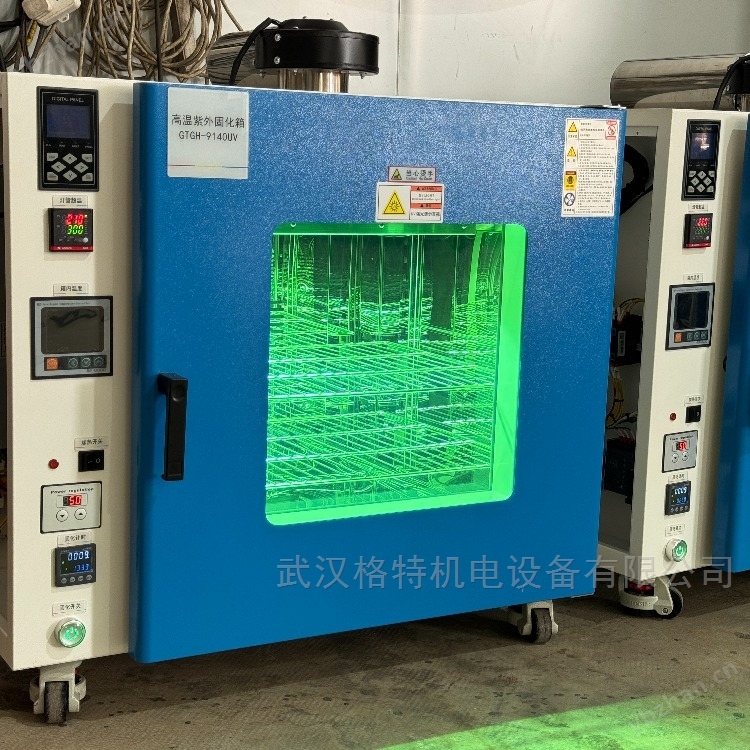

UV-LED light source curing box

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

UV-LED light source curing boxCompared to traditional mercury lamp UV curing equipment, UV-LED curing boxes have advantages such as no thermal radiation, long lifespan, and instant use. They are widely used in industries such as electronics, healthcare, and printing for high-precision curing needs.

UV-LED light source curing boxCore functions and features

Efficient UV-LED light source:

Using high-power LED chips, emitting single wavelength ultraviolet light (such as 365nm), with concentrated energy and fast curing speed.

The lifespan of the light source is over 20000 hours, with a low attenuation rate and much lower maintenance costs than traditional mercury lamps.

Precise light intensity control:

Adjustable light intensity (usually 500-5000mW/cm ²), suitable for different curing depth requirements (surface/deep curing).

Equipped with a digital radiometer to monitor UV intensity in real-time and ensure process stability.

Low thermal radiation design:

The characteristics of LED cold light source are low working temperature (<60 ℃), avoiding deformation of heat sensitive materials (such as plastics and films).

Modular structure:

Multiple lamp heads can be freely combined, supporting point light source, line light source, or surface light source configurations, suitable for curing complex workpieces.

Optional automation components such as conveyor belts and rotating tables are available to achieve assembly line operations.

Energy conservation and environmental protection:

The energy consumption is only 10% -30% of traditional mercury lamps, with no ozone emissions and no need for preheating, meeting green manufacturing standards.

Typical application scenarios

Electronic packaging: UV glue curing for IC chips, curing of protective layer for FPC flexible circuit boards.

Medical equipment: catheter bonding, dental resin curing.

3D printing: post-processing of light cured (SLA/DLP) models.

Printing and coating: UV ink, fast curing coating, especially suitable for substrates such as PET and acrylic.

Example of Technical Parameters

|Project | Parameter Range|

|---------------|--------------------------|

| UV波长 | 365 nm/385nm/395nm/405nm |

|Light intensity | 500-5000mW/cm ² (adjustable)|

|Illumination area | 50mm × 50mm to customized large size|

|Working distance | 5-30mm (affecting the uniformity of light intensity)|

|Power input | AC 220V or low voltage DC|

5. Comparison with traditional mercury lamp UV curing

|Comparison | UV-LED curing box | Traditional mercury lamp UV equipment|

|------------------|--------------------------------|--------------------------------|

|Wavelength | Single wavelength, precise matching of photoinitiators | Wide spectrum (including infrared), high thermal effect|

|Lifespan | 20000+hours | 500-1000 hours (requires frequent replacement)|

|Energy consumption | Low (about 100-500W) | High (1-5kW)|

|Curing speed | Fast (second level response) | Requires preheating, curing speed is limited by power|

|Environmental friendliness | Mercury free, ozone free | Mercury containing, requiring special treatment for discarded lamp tubes|

6. Selection suggestions

Wavelength selection: Match based on the characteristics of the material's photoinitiator (e.g. 365nm is suitable for most epoxy resins).

Light intensity requirement: High viscosity adhesives or thick coatings require higher light intensity (≥ 3000mW/cm ²).

Extension function: When pipeline integration is required, select an intelligent control model that supports external triggering.

7. Precautions

Avoid direct exposure to UV light on the skin or eyes, and wear protective equipment during operation.

Regularly clean the LED lens to prevent dust from affecting the efficiency of the light path.

Long term storage requires turning off the power to prevent LED chips from getting damp.

If customized solutions are needed (such as multi wavelength combination, non-standard irradiation head design), specific process parameters can be provided for further communication.