-

E-mail

2623729929@qq.com

-

Phone

13871140023

-

Address

Baishazhou Fenghuo Steel Market in Hongshan District, Wuhan City

Wuhan GeTe Electromechanical Equipment Co., Ltd

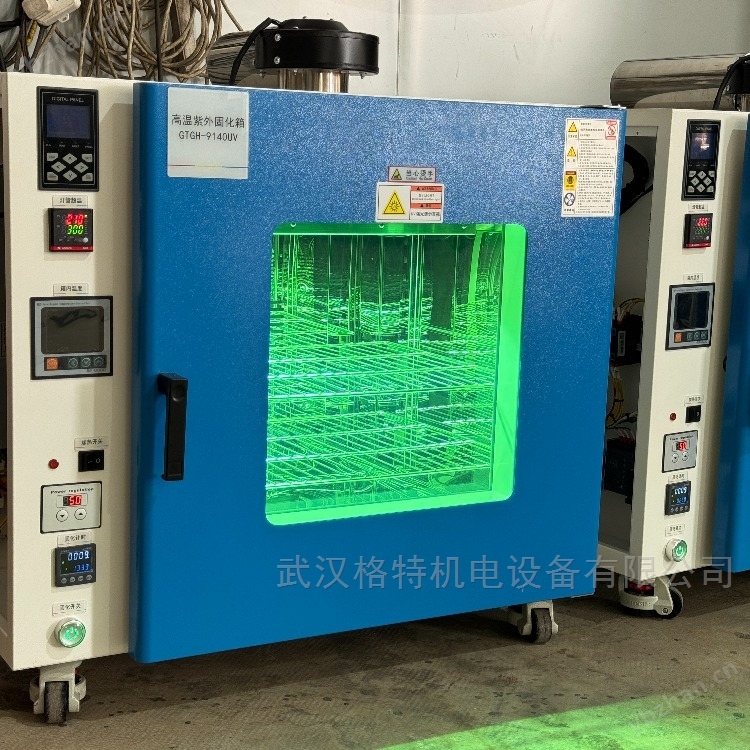

UV curing box

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

1. Product Overview

UV curing boxIt is a specialized equipment that uses high-intensity ultraviolet (UV) light sources to trigger the curing of photosensitive materials. By activating the photoinitiators in materials such as coatings, inks, adhesives, etc. with specific wavelengths of ultraviolet light (such as 365nm, 395nm), rapid curing can be achieved (in seconds to minutes). This type of equipment is widely used in fields such as electronic manufacturing, printing and packaging, and the automotive industry due to its high efficiency, environmental friendliness, and low energy consumption.

---

2. Core functions and features

Efficient UV light source:

Using mercury lamps or UV-LED light sources, with a wavelength range covering 280-405nm, suitable for different needs of photoinitiators.

The light intensity can be adjusted (500-5000mW/cm ²) to meet the requirements of surface or deep curing.

Uniform illumination system:

Optimize the design of the reflective cavity or multi lamp array layout to ensure uniform irradiation in the working area (uniformity ≥ 90%).

precise control:

The time controller (adjustable from 1 second to 999 minutes) and irradiation monitoring module ensure process repeatability.

safety protection:

Equipped with UV resistant windows, emergency stop switches, and over temperature protection, in compliance with CE/UL safety standards.

Flexible Expansion:

Support conveyor belts (continuous production), inert gas interfaces (anti-oxidation), or customized optical systems.

---

3. Typical application scenarios

electronics industryPCB board solder mask ink curing, micro component UV glue fixation.

printing and packagingDrying of paper/plastic UV ink and curing of metal surface coating.

medical deviceDisposable consumables bonding, dental resin molding.

industrial manufacturingAutomotive glass sealant and optical lens coating curing.

---

4. Examples of Technical Parameters

|project|parameter range|

|----------------|------------------------------|

|UV wavelength | 280-405nm (commonly 365nm/395nm)|

|Power | 300W-5kW (optional according to size)|

|Effective irradiation area | 100mm × 100mm to customized size|

|Curing time | 1 second -30 minutes (programmable)|

|Power Requirements | AC 220V/380V, 50/60Hz|

---

5. Comparison of Equipment Types

Traditional mercury lamp curing box:

Wide spectrum (including infrared), high thermal effect, suitable for curing thick coatings, but high energy consumption, requiring regular replacement of the lamp tube.

UV-LED curing box:

Cold light source, single wavelength, energy-saving and long-lasting (over 20000 hours), more suitable for heat sensitive materials.

---

6. UV curing boxPrecautions

Wear UV protective goggles during operation to avoid direct exposure to ultraviolet rays.

Regularly clean the reflector cover and lamp tube to prevent dust from reducing light efficiency.

Ventilation should be maintained around the curing box to avoid the accumulation of volatile substances.