-

E-mail

whhshjd@163.com

- Phone

-

Address

Wuhan Economic Development Zone Economic Development Zone Wanda Office Building B4-506

Wuhan Haosiheng Electromechanical Co., Ltd

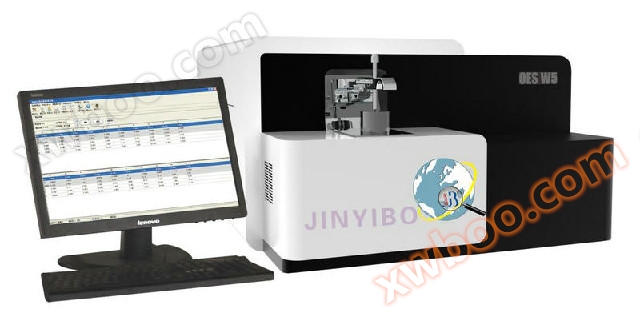

W5 type full spectrum direct reading spectrometer

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

W5 type full spectrum direct reading spectrometerHaving the ability to quickly determine elements in metal material samples. The optical system adopts a CMOS detector with a spectral range covering all typical materials. It can accurately and reliably analyze both low and high content elements. The company has accumulated years of production experience in the field of spectroscopy, and has designed this new and more cost-effective full spectrum direct reading spectrometer for different materials and requirements. It can meet the applications of quality monitoring, material grade identification, material research and development in the metal manufacturing, processing and metal smelting industries.

Black Technology 4: Intelligent Integrated Gas Circuit Module

Intelligent argon gas flow design and dust collection and cleaning device

Argon injection technology effectively eliminates plasma drift during the excitation process, ensuring that CCD detectors can observe light signals in high-temperature areas, improving accuracy and stability.

After excitation, pulsed argon gas is blown to improve dust removal efficiency and enhance the short-term and long-term stability of the instrument.

Black Technology V: Intelligent Vacuum Measurement and Control

The vacuum system is fully programmable, reducing the operating time of the vacuum pump while ensuring the vacuum degree,

Dual level setting, enabling standby vacuum operation when the instrument is not running.

Multi level vacuum isolation measures and the addition of oil filtration devices ensure that optical components work in a reliable environment.

Black Technology 6: Lens Cleaning Device

Stainless steel vacuum ball valve has good isolation effect when cleaning lenses.

Single panel lens design, easy to disassemble and assemble.

The cross mechanical device effectively protects the optical system without lifting the isolation.

Black Technology 7: Computers and Readout Systems

Computers and mobile phones (or PADs) can display synchronously for convenient panel operation.

High resolution multi CMOS readout system and FPGA, DSP, and ARM technologies for data acquisition.

Ethernet and TCP/IP protocols enable high-speed and reliable data transmission.

Data can be transmitted remotely and fully networked. Real time convenient monitoring and control of instrument operation status.

The data can be cloud printed.

Black Technology 8: Specialized Spectral Analysis Software

The specialized spectrometer software for producing standard spectrometers has a user-friendly interface and standardized functions.

The instrument is equipped with multiple factory calibration curves, more material analysis methods, and advanced solutions in the software.

The measurement upper and lower limits of the standard curve can be extended on site according to the user's material requirements.

Other black technologies:

Automatic optical path calibration

Low consumption of argon gas

Universal adjustable sample adapter

Matrix extension function

Standardized parameter modification

Sample control correction function

Safe, open and convenient design

Real time display of results, customizable printing report function for users

Software rapid diagnosis

Easy interface operation

Reliable factory calibration function

Technical parameters:

| project | index |

| Detecting the substrate | 13 substrates including iron-based, copper based, aluminum based, nickel based, cobalt based, magnesium based, titanium based, zinc based, lead based, tin based, silver based, manganese based, chromium based, etc |

| optical system | Pascal Runge Roland circular full spectrum vacuum optical system |

| wavelength range | 165-580nm (can be equipped with upper and lower limit detectors to expand the wavelength range) |

| Grating focal length | 400mm |

| detector | High resolution multi CMOS image sensor |

| light source | DDD digital excitation light source, high-energy pre combustion technology (HEPS) |

| discharge frequency | 100-1000Hz |

| Discharge Current | Big 400A |

| detection time | Depending on the type of sample, it usually takes around 25 seconds |

| electrode type | Tungsten jet electrode |

| analytical gap | Sample stage analysis gap: 3.4mm |

| vacuum system | Vacuum software automatic control and monitoring |

| Light room constant temperature | 34 ℃, automatic temperature monitoring |

| Purity of argon gas | 99.999% |

| Argon pressure | 0.5MPa |

| Working power supply | AC220V 50/60Hz |

| Instrument dimensions | 860*680*438mm |

| Instrument weight | About 100kg |

Application industries: Steel industry, non-ferrous metals, alloy casting, mechanical processing, commodity inspection and quality control, material research