-

E-mail

13810083196@163.com

-

Phone

13911237038

-

Address

Building 2, Chaomingyuan, Boxing 10th Road, Yizhuang Economic and Technological Development Zone, Beijing

- High and low temperature alternating cycle test chamber

- Programmable constant temperature and humidity chamber

- thermal shock chamber

- Step in aging test room (burning machine room)

- High and low temperature damp heat test chamber

- Rapid temperature change test chamber

- Walk in constant temperature and humidity laboratory

Beijing Pusanda Instrument Technology Co., Ltd

Walk in constant temperature and humidity test cabinet

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Walk in constant temperature and humidity test cabinetTemperature and humidity control system:

A: Temperature controller: 7-inch color LCD touch screen programmable controller, in both Chinese and English, with high contrast and adjustable backlight function LCD display controller.

B: Controller specifications:

Accuracy: Temperature ± 0.1 ℃+1 digit

Resolution: Temperature ± 0.01,

Temperature slope: adjustable from 0.1 to 9.9

Equipped with upper and lower limit standby and alarm functions

Temperature input force signal PT100

C: Screen display function:

Direct display of temperature setting (SV) and actual (PV) values

Can display the current program execution number, segment number, remaining time, and number of cycles

Accumulated operation time function

Has a separate program editing screen.

The screen display protection function can be set to timer, TIMER, or manually turned off

D: Program capacity and control functions:

Available program groups: 100 PATTEN

Available memory capacity: 10000 SEGMENT in total

Repeatable command execution

SEGMENT time setting: 0-9999Hour59Min

Equipped with power-off program memory, it automatically starts and continues to execute program functions after power restoration

Equipped with RS-232 communication interface

USB data interface, capable of exporting experimental data.

Real time display of graphical curves during program execution

It has the function of scheduled startup and shutdown

Has date and time adjustment function

Button and screen lock (LOCK) function

Refrigeration system: using French Taikang fully enclosed refrigeration compressor unit (or American Gulun compressor)

Refrigeration compressor: In order to ensure the cooling rate and achieve extremely low temperature requirements of the test chamber, the test chamber adopts a stacked refrigeration method

The design of refrigeration systems should incorporate energy regulation technology, which is an effective way to ensure that the energy consumption and cooling capacity of the refrigeration system can be effectively adjusted while the refrigeration unit is operating normally, reducing the operating costs and failure rates of the refrigeration system to a more economical state.

Refrigeration auxiliary components: air-cooled coil condenser, finned multi-stage evaporator. The main refrigeration accessories and control components are imported, such as the American "Aigo" drying filter, the Italian "Castello" solenoid valve, etc;

Refrigerant: R404A is used

Cooling method: air cooling

Installation method: Split outdoor

Heater: finned heat dissipation tube type nickel chromium alloy electric heating method

Humidification system: External humidifier, water addition can be done automatically or manually

The constant temperature and humidity laboratory adopts multi-faceted power consumption and temperature protection measures, with overcurrent protection, switch power overvoltage protection, overheating maintenance, and shrinkage maintenance designed at every key point of the laboratory work. And the actual operation is simplified, the functions are complete, the cost-effectiveness is high, and customers can apply with peace of mind.

Protection devices: no fuse switch, compressor high and low pressure protection switch, compressor overheating, overload, overcurrent protection, refrigerant high pressure protection switch, fault warning system, electronic alarm, leakage protector, fan overheating protection, phase sequence protection, overtemperature protection, exhaust valve, compressed air regulating switch, fuse.

Room structure:

The chamber adopts a combined storage plate structure, which can be easily assembled on the buyer's site

The indoor wall material of the laboratory is SUS304 stainless steel plate, and the outer wall material is high-quality cold-rolled steel plate. The outer surface is electrostatically painted with a light gray white color; 100mm polyurethane foam and high-density aluminum silicate insulation layer in the middle

The workshop floor is made of anti slip patterned steel plate, and the anti slip slope should ensure that the trolley can easily enter and exit the workshop

The laboratory adopts a double door structure, equipped with internal and external handles

Install moisture-proof lighting on the top of the workspace, with one cable lead out hole on each side (which can be sealed when not in use)

The structure of the laboratory should be designed reasonably, manufactured with excellent technology, aesthetically pleasing both inside and outside surfaces, and the stainless steel plates and electrostatic spraying surfaces should be smooth and free of defects such as bumps and scratches.

Studio size: customized according to requirements, with volumes ranging from 1m ³ to 100 cubic meters

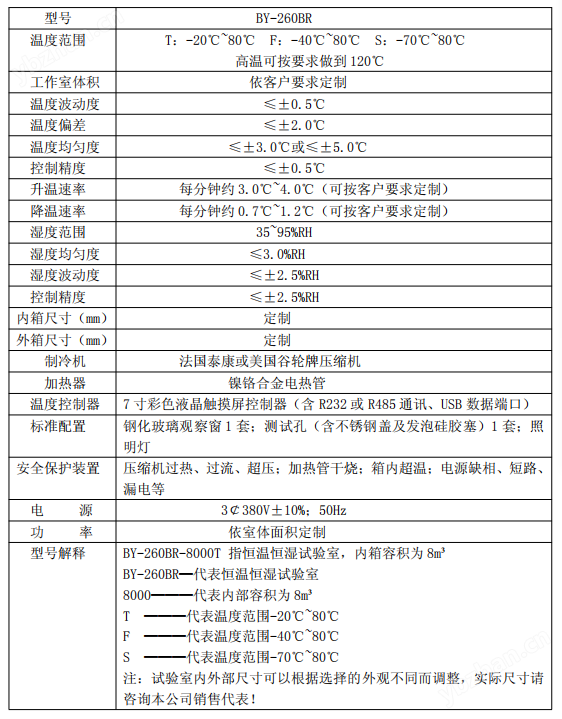

Walk in constant temperature and humidity test cabinetPurpose: This laboratory is suitable for adaptability testing of large components of aerospace, automotive, electrical appliances, hardware and other products under high temperature, humidity, and temperature humidity testing environments, as well as screening methods for product analysis and evaluation. It can be used to test large components, assemblies, and complete products, from computers and copiers to vehicles and machines, and can also be used as a testing environment to test the storage life of food and drugs. Technical specifications and parameters:

The walk-in constant temperature and humidity laboratory is designed to meet users' requirements for large volume testing spaces. It can be divided into integral welding and assembly types structurally. Among them, there are over thirty sizes and sixteen types of refrigeration units that can be matched with each other in the assembled type alone.

The walk-in constant temperature and humidity laboratory can be used to test large components, assemblies, and complete products, from computers and copiers to vehicles and machines. It can also serve as a testing environment to test the storage life of food and drugs.

Installation and debugging:

(1) Home delivery, complete system installation with quality and quantity as required by the contract, and our engineering and technical personnel conduct debugging.

(2) The product manual provides installation and interface information, which greatly facilitates equipment maintenance.

(3) Provide training for equipment users to enable them to operate the equipment independently in the future. Master the operation, daily maintenance, and simple repairs of the product.

Warranty Commitment:

From the date of acceptance, a two-year warranty will be provided (except for damages caused by natural disasters, abnormal electricity, improper use, or improper maintenance, our company will provide free repairs).

For services beyond the warranty period, only corresponding cost fees will be charged.

Any problems that occur during the use of the equipment should be responded to within 24 hours, and maintenance engineers and technicians should be promptly dispatched to handle and solve the problems.

Promise to provide lifelong free technical support.