-

E-mail

2628879629@qq.com

-

Phone

18066558480

-

Address

Standard Factory Building on Chuangye Avenue, New Industrial Park, High tech Zone, Xi'an City

Product Categories

Xi'an Xiangyuan Technology Co., Ltd

Xiangyuan Petrochemical Industry Magnetic Flip Plate Liquid Level Gauge

NegotiableUpdate on 12/20

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

Overview

The application principle of magnetic flap level gauges in the petrochemical industry is mainly based on magnetic coupling work. The main body of the liquid level gauge is a non-magnetic material tube, called the main tube or shell, which contains a magnetic floating ball inside. This floating ball is connected to the container through a flange or other interface, so that the liquid level inside it is consistent with the liquid level in the container.

Product Details

1、 Product Introduction:

The application principle of magnetic flap level gauges in the petrochemical industry is mainly based on magnetic coupling work. The main body of the liquid level gauge is a non-magnetic material tube, called the main tube or shell, which contains a magnetic floating ball inside. This floating ball is connected to the container through a flange or other interface, so that the liquid level inside it is consistent with the liquid level in the container.

Due to the embedded magnet in the float, when the liquid level of the container changes, the float will rise and fall accordingly. The external panel of the liquid level gauge is equipped with a column display, which is composed of a cylindrical body (i.e. magnetic flip column) consisting of two half cylinders in red and white. When the floating ball rises and falls with the liquid level, its magnetism will be transmitted to the rotating column display through the shell, pushing the rotating column to rotate 180 °. The color outside the flip column display will change after flipping 180 degrees, and the junction of the two colors is the current liquid level height.

In addition, if the magnetic flap level gauge is equipped with a remote transmitter, its working principle is to use a magnetic float to act on a magnetic spring switch, causing a change in the number of resistors connected to the circuit. In this way, the sensor part can generate resistance signals corresponding to changes in liquid level. Through a signal converter, this resistance signal can be converted into a 4-20mA current signal.

Magnetic flap level gauges have multiple advantages. Firstly, its structure is compact, consisting of a flipper and a magnet, making it easy to install and not taking up too much space. Secondly, it is easy to use and does not require complex circuits or data processing equipment. The important thing is that the measurement effect of this product is accurate. Due to the highly precise manufacturing of magnets and flippers, flippers can react promptly when the liquid level changes. This simple and reliable mechanical interaction can accurately reflect the level of liquid. In addition, it is also suitable for high temperature and high pressure environments, and its measurement principle is not affected by temperature and pressure, so it is very suitable for liquid level detection under similar conditions.

In the petrochemical industry, there are also various types of applications, including anti-corrosion magnetic flap level gauges, insulation jacket flap level gauges, high-temperature and high-pressure magnetic flap column level gauges, etc., to adapt to various environments and usage scenarios.

2、 Application scenarios

3、 Technical parameters

| medium pressure | Stainless steel ≤ 10Mpa, anti-corrosion ≤ 2.5Mpa |

| medium density | ≥0.5g/cm3 |

| medium temperature | -20~400℃ |

| medium viscosity | ≤10-4m2/S |

| measurement accuracy | ±10mm |

| Installation method | Flanged side mounted type |

| Protection level | IP65 |

| Install flange | According to user requirements |

| Discharge flange | Default is DN25-GB |

| Float specifications | φ 51, φ 57 (wall thickness depends on pressure and temperature) |

| Float material | 304/316L/PP/PVC/PTFE lined |

| functional facilities | Standard type (on-site flipping display) Remote transmission type (on-site flipping display+signal remote transmission) Alarm type (local flip panel display+alarm switch) Remote alarm capability (on-site flipping display+signal remote transmission+alarm) |

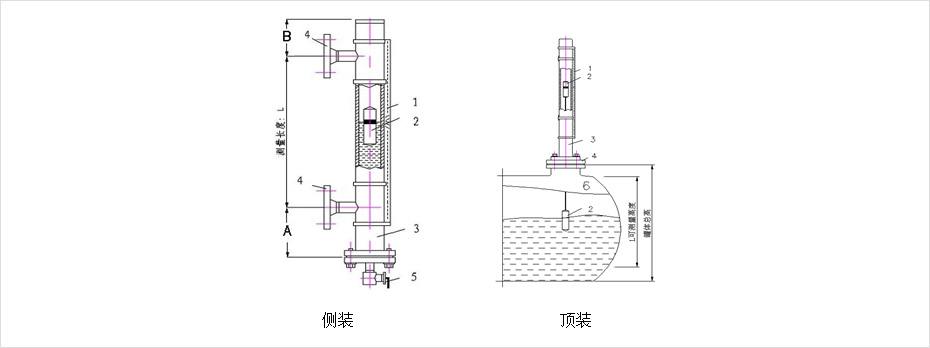

4、 Installation method

5、 Accessories

1. Transmitter

The transmitter is tied to the outside of the main tube of the magnetic flap level gauge with a clamp, so that it is in the same magnetic coupling system as the level gauge. When the magnetic float moves up and down with the liquid level, the dry spring chip group corresponding to the liquid level position is affected and moved by the magnetic field inside the float, and the resistance chain value changes. The changed resistance signal is converted into a 4-20mADC standard signal through a conversion module and transmitted to the secondary instrument PLC、DCS, Thus achieving the purpose of liquid level display, control, regulation, and alarm.

Fixed on the magnetic flip plate measuring cylinder with clamps; The transmitter box can be installed at the top or bottom;

Attention: The transmitter is an electronic precision component and is strongly affected by the environment. The normal operating temperature range is -40~85 ℃. Beyond this range, there may be unclear display or communication interruption.

2. Alarm switch

The control switch consists of a reed switch and circuit module, with a compact structure, sturdy and durable, and a holding (memory) type control switch. The liquid level control switch is fixed in a bundled form on the outside of the magnetic float level gauge/magnetic flap level gauge, so that it is in the same magnetic field system as the level gauge. When the magnetic float moves up and down with the liquid level, the reed switch corresponding to the liquid level position is attracted by the magnetic field inside the float, and the changing signal is converted into a passive switch signal output through a conversion module.

Fixed on the magnetic flip plate measuring cylinder with clamps; The fixed position can be adjusted, and users can adjust the height according to their needs.

Attention: The transmitter is an electronic precision component and is strongly affected by the environment. The normal temperature range for use is -40 ℃ to 85 ℃. Exceeding this range may result in unclear display or communication interruption.

Similar Product Recommend