-

E-mail

sales@chotest.com

-

Phone

18928463988

-

Address

No. 1001, Xili Xueyuan Avenue, Nanshan District, Shenzhen, China

Shenzhen Zhongtu Instrument Co., Ltd

Zhongtu Instrument White Light Interference 3D Surface Proformer

- Model

- Nature of the Manufacturer

- Producers

- Product Category

- Place of Origin

SuperViewW Image InstrumentWhite light interference 3D surface profilometerCombining the advantages of multi scenario adaptability, high-precision measurement, and intelligent operation, it can solve measurement problems such as ultra smooth/rough materials, nanometer/micrometer level accuracy, and low batch detection efficiency in one stop.

1、 Core functions of the product

1. Measurement capability: Covering all types of sample surfaces without switching measurement modes, suitable for diverse detection scenarios ranging from precision components to batch workpieces.

2. Automation experience: The joystick facilitates easy control of all axis positions, supports array based multi area measurement, automatic Mark point positioning and calibration, and batch sample switching measurement point positions without the need for repeated debugging.

3. Data processing and export: Built in four data processing modules including denoising and filtering, five analysis functions including roughness and geometric contour, supporting Word/Excel/PDF format report export to meet quality inspection archiving and data analysis needs.

4. Stability and safety guarantee: The air flotation isolation base isolates vibration interference, and the 0.1nm resolution environmental noise evaluation function ensures accurate data; Dual lens collision protection and automatic light source shutdown design reduce equipment wear and operational risks.

2、 Product Core Highlights

1. Full scene coverage: The single scanning mode is suitable for ultra smooth to rough, mirror to fully transparent/black materials, and can accurately measure parameters such as roughness, flatness, and micro profile of workpieces from nanometer to micrometer levels, without the need to replace equipment, to meet the testing needs of various types of products.

2. High precision+wide range dual breakthrough: The composite EPSI reconstruction algorithm solves the bottleneck of traditional technology, and the automatic stitching function supports multiple modes such as square and circular. Thousands of images are seamlessly stitched together, and ultra smooth concave curved scanning can also achieve seamless reconstruction without overlapping gaps.

3. Efficient automation to reduce costs and increase efficiency: One click completion of single/multi area automatic measurement and batch analysis, programmable measurement function can preset processes to achieve one click operation, short measurement time for individual fine components, greatly improving detection throughput.

4. Self developed software platform: Xtremevision Pro second-generation 3D measurement software platform is compatible with multiple models and has stronger scalability. Integrated image scanning, 3D analysis, image measurement, and automated measurement modules, compatible with all 3D instrument models in the Zhongtu W/VT/WT series. Supports automatic switching between white light interference and confocal microscopy, allowing for direct measurement of parameters such as distance, angle, radius, etc. of microscopic plane contours. Equipped with flexible automatic stitching function, it allows for unlimited customization of measurement areas.

3、 Application Fields

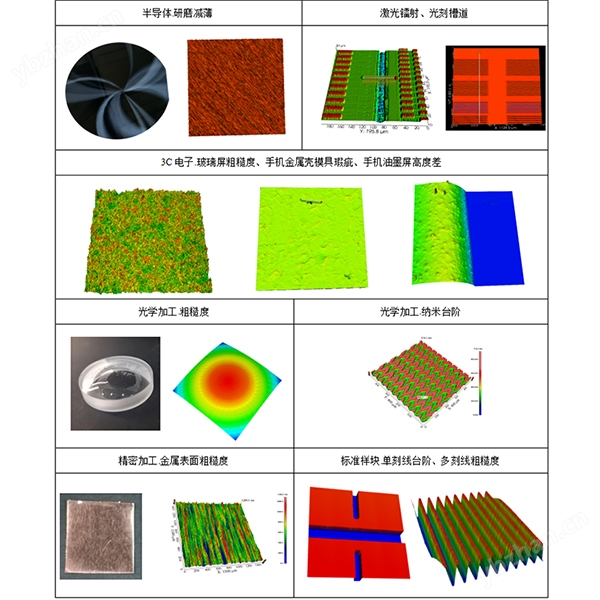

Zhongtu InstrumentWhite light interference 3D surface profilometerWidely used in precision manufacturing, electronic semiconductors, automotive components, new materials, medical devices and other fields, it measures and analyzes the surface morphology characteristics of various products, components and materials, such as roughness, waviness, surface contour, surface defects, wear, corrosion, pore gap, step height, bending deformation, processing, etc.

If you need to obtain product demonstration videos, industry case manuals, or accurate quotations, please feel free to contact Zhongtu Instrument at any time. We will provide you with one-on-one professional consulting services!

Please be advised that due to market development and product development needs, the relevant content in this product information may be updated or modified at any time based on actual circumstances without prior notice. We apologize for any inconvenience caused.