-

E-mail

1225767627@qq.com

-

Phone

13581986832

-

Address

Shahewangzhuang Industrial Park, Changping District, Beijing

Beijing Guance Jingdian Instrument Equipment Co., Ltd

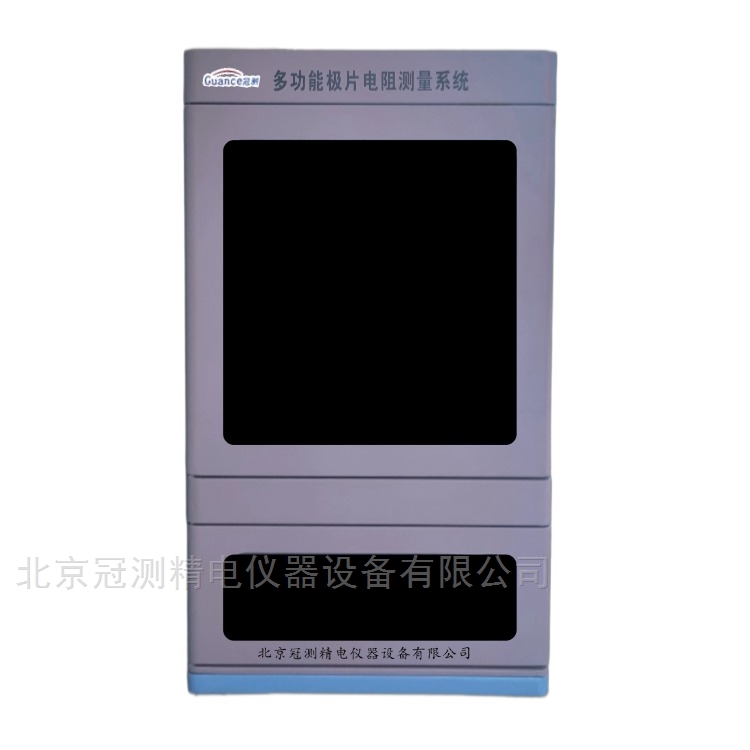

In the field of lithium-ion battery manufacturing, electrode resistance is a key indicator for evaluating the performance of electrode materials, which directly affects the energy efficiency and cycle life of the battery. With the rapid development of the new energy industry, traditional measurement methods are no longer able to meet the requirements of modern production for accuracy and efficiency, and multifunctional pole piece resistance measurement systems have emerged.

System architecture design

The modern polarizer resistance measurement system adopts a modular design concept, integrating multiple functional units such as precision measurement, automatic control, and environmental simulation. The system effectively avoids the interference of lead resistance on measurement results and ensures data accuracy through a special four terminal measurement method. The system can automatically adjust the measurement mode based on the characteristics of different materials, achieving comprehensive coverage from low resistance to high resistance materials.

Multi channel testing capability is the core advantage of the system. Through precise switching matrices, the system can quickly measure multiple measurement points simultaneously, greatly improving detection efficiency. This design is not only suitable for fine research in laboratories, but also meets the high-speed testing needs on production lines. With the intelligent clamping device, the system can maintain a stable contact state, ensuring consistent measurement conditions every time.

Intelligent analysis function

The software platform of the system integrates powerful data analysis capabilities. Through a visual interface, operators can intuitively observe the resistance distribution on the surface of the polarizer and quickly identify areas of uneven coating. The software also provides trend analysis function, which can track the changes in resistance values over time and provide reference for process optimization.

In terms of quality control, the system has established a comprehensive database management mechanism to fully record the testing data of each batch of polarizer. Through statistical analysis, the system can automatically identify abnormal fluctuations in the production process and achieve early warning of quality issues. This preventive monitoring mode helps enterprises establish a more proactive quality management system.

Application value manifestation

This measurement system has demonstrated significant application value in the field of battery manufacturing. In the research and development stage, researchers can quickly evaluate the impact of different formulations and processes on the conductivity of electrode sheets through high-precision data provided by the system, effectively shortening the research and development cycle. In the production process, the system's efficient detection capability provides quality assurance for large-scale production.

After a certain battery production enterprise introduced this system, not only did it improve the detection efficiency, but more importantly, through the system's analysis function, it discovered process defects that were previously difficult to detect. Through in-depth analysis of measurement data, the enterprise optimized the coating process parameters and significantly improved product consistency. These improvements are directly reflected in the performance enhancement of battery products.

Future development direction

Faced with the continuous emergence of new battery materials, the electrode resistance measurement system will continue to evolve. Future systems will pay more attention to the improvement of intelligent diagnostic capabilities, by introducing advanced algorithm models to achieve deep mining and automatic analysis of measurement data. At the same time, the system will further enhance its integration with the production line, achieving real-time interaction between measurement data and manufacturing execution systems.

With the development of industrial Internet technology, the measurement system will gradually migrate to the cloud to achieve cross plant data sharing and collaborative analysis. This transformation will promote the establishment of a more comprehensive quality traceability system in the battery manufacturing industry, providing strong support for technological progress in the industry.

Conclusion

The multifunctional polarizer resistance measurement system provides a new quality monitoring solution for battery manufacturing through innovative design and intelligent analysis functions. This system not only improves detection efficiency and accuracy, but more importantly, through data insights, helps enterprises optimize production processes and promote continuous improvement of product quality. Against the backdrop of rapid development in the new energy industry, this comprehensive measurement solution will play an increasingly important role.