-

E-mail

info@coremorrow.com

-

Phone

17051647888

-

Address

1st Floor, Building I2, Entrepreneurship Incubation Industrial Park, No. 191 Xuefu Road, Nangang District, Harbin City, Heilongjiang Province

Harbin Xinmei Technology Co., Ltd

Capacitive micrometer is a high-precision measuring instrument based on the principle of capacitive sensing, mainly used for non-contact detection of physical quantities such as small displacement, thickness, gap, vibration, etc. It is widely used in precision manufacturing, semiconductor, optical technology, aerospace and other fields that require high measurement accuracy. It is a key supporting measuring component for piezoelectric nanopositioning, micro nano processing equipment, etc. Xinming's new C2D18 capacitive micrometer has a 2mm large stroke measurement capability. While achieving breakthroughs in measurement range, it always adheres to nanometer level measurement accuracy, balancing the core requirements of wide range and high precision.

1、 New product recommendation: 2mm range capacitance micrometer C2D18

The capacitance micrometer converts the measured physical quantity, such as small displacement changes, into changes in capacitance values, and then converts the capacitance changes into readable electrical signals through signal processing circuits, thereby achieving accurate measurement of small quantities. Its measurement resolution can reach the nanometer level, making it one of the core tools in micro nano scale measurement.

On the basis of the existing capacitive micrometer product line, we have added a 2mm range capacitive micrometer C2D18, further improving the full range coverage from 100 μ m to 2mm. This product aims to provide a wider range of nanometer level sensing capabilities for high-end precision machining, piezoelectric positioning system matching, industrial testing, and scientific research experiments, providing a more comprehensive solution for large stroke and small quantity measurement, while making the overall measurement scheme more flexible and adaptable.

The three core advantages of the new product are:

1. Range breakthrough, covering a wider range of scenarios: The 2mm ultra large range product has doubled in size compared to the original 1mm large range product, and can meet multi-scale measurement needs from micrometer to millimeter without frequent equipment replacement, adapting to a wider range of precision detection scenarios.

2. Adhere to precision and maintain nanometer level performance: maintain nanometer level resolution and repeatability, effectively offset environmental effects such as temperature drift and electromagnetic interference through optimized design, and ensure measurement stability; Even within a full range of 2mm, linearity still maintains nanometer level accuracy.

3. Compatible with all scenarios of piezoelectric positioning: compatible with tomorrow's piezoelectric nano positioning platform and controller, forming an integrated solution of "positioning measurement closed-loop correction", with strong ecological synergy; Fast response time, able to * * match dynamic closed-loop control requirements.

2、 Application fields of capacitance micrometer

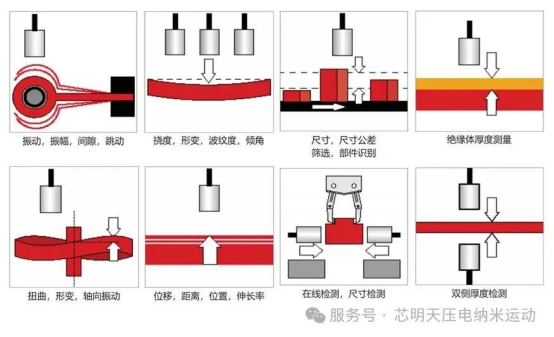

The capacitance micrometer, with its unique advantages of nanometer level accuracy, non-contact measurement, fast response, and high stability, has become a core tool in the field of modern precision measurement and is widely used in multiple industries that require extremely high accuracy

1. Semiconductor and Microelectronics Industry

Full process monitoring of wafer processing: measurement of wafer thickness and warpage, analysis of surface defects, positioning of mask plates, and feedback of multi axis displacement of wafer frustum;

Chip packaging and testing: alignment between packaging layers, chip bonding pressure and gap control, etc.

2. Precision Optical Technology

Optical component manufacturing: measurement of lens curvature, parallelism, center thickness, control of optical component coating thickness, calibration of optical prism angle, detection of OLED panel thickness uniformity, measurement of glass substrate warpage, etc.

3. Precision manufacturing field

Ultra precision machining and monitoring: machine tool spindle rotation accuracy detection, precision guide rail straightness measurement, mold wear monitoring, micro nano structure displacement, deformation and vibration detection, etc.

4. Aerospace field

Aircraft manufacturing: precise measurement of fuselage dimensions, detection of interlayer gaps in composite materials, vibration analysis of core components such as aircraft engine blades, monitoring of the deployment status of spacecraft solar panels, etc.

5. Automotive and Energy Equipment

Quality control in automobile manufacturing: detection of changes in brake disc thickness, measurement of engine cylinder flatness;

Manufacturing of new energy equipment: measurement of lithium battery electrode thickness, detection of fuel cell membrane electrode assembly thickness, monitoring of wind turbine blade deformation, etc.

6. Research and General Measurement

Equipment matching: It can be used as a sample stage position monitoring sensor for scanning probe microscopes, confocal microscopes and other equipment, expanding the longitudinal measurement range of the equipment;

Materials and Environmental Testing: Composite material elastic modulus testing, fatigue testing, small deformation monitoring, displacement detection and interference free precision positioning in special environments such as vacuum, low temperature, and strong magnetic fields.

The Xinming capacitance micrometer is suitable for high-precision positioning, angle/linear vibration measurement, thickness detection, rotating machinery gap measurement, jumping measurement, autofocus or zeroing, dielectric constant measurement, astronomical telescope lens positioning, outer diameter measurement, deformation measurement, etc.

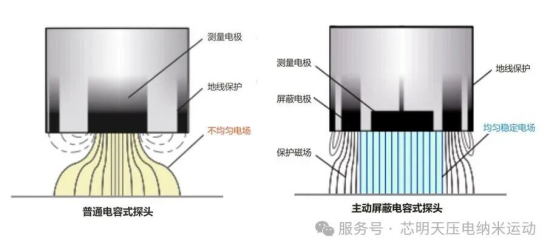

3、 Core features of Xinming capacitance micrometer

1. Ultra high precision and resolution

The measurement resolution can reach the nanometer level, with high measurement accuracy, which can meet the demanding requirements of micro nano scale measurement.

2. Non contact measurement

During the measurement process, there is no mechanical contact between the sensor and the object being measured, which will not cause scratches or wear on the surface being measured, nor will it cause measurement errors due to contact forces. It is suitable for measuring fragile workpieces, flexible materials, or high-speed moving objects.

3. Fast response speed

The detection of capacitance changes is not affected by mechanical inertia, and the response time of the signal processing circuit can reach microsecond level. It can capture dynamic changes such as small vibrations, high-speed displacements, etc. in real time, and can be used for dynamic measurement and closed-loop control scenarios.

4. Good stability and strong anti-interference ability

Can effectively counteract environmental disturbances such as temperature drift and power fluctuations; Capacitive sensors have a stable structure, no vulnerable parts, high long-term stability, and low maintenance costs.

5. Flexible measurement range

The CxDxx series of capacitance micrometers covers a range of 100 μ m~2mm, enabling large-scale measurements from micrometer to millimeter level. It can meet the needs of small displacement measurement in micro nano machining and also adapt to gap detection in precision machinery.

6. Compatible with multiple tested materials

When the measured object has a certain conductivity and meets the conditions, it can be measured without being affected by the material, and is suitable for precise detection of various materials such as metals, semiconductors, glass, ceramics, etc.

4、 The full series product matrix of Xinming capacitance micrometer

1) Sensing probe

We provide a complete product line of capacitance micrometers to meet the needs of different accuracies, ranges, and dynamic performance.

Cylindrical capacitive sensor

| model | C2D18 |

| measurement range | 2000μm |

| Static resolution | 20nm |

| Dynamic resolution (1kHz) | 800nm |

| linearity | 800nm |

| repetitiveness | 40nm |

| Probe size | φ18×18.5mm |

| model | C01D10 | C02D10 | C05D10 | C1D10 |

| measurement range | 100μm | 200μm | 500μm | 1000μm |

| Static resolution | 1.25nm | 2.5nm | 5nm | 10nm |

| Dynamic resolution (1kHz) | 50nm | 100nm | 200nm | 400nm |

| linearity | 50nm | 100nm | 200nm | 400nm |

| repetitiveness | 2.5nm | 5nm | 10nm | 20nm |

| Probe size | φ10×18.5mm | |||

Square capacitive sensor

| model | C02F13 |

| measurement range | 200μm |

| Static resolution | 2.5nm |

| Dynamic resolution (1kHz) | 100nm |

| linearity | 100nm |

| repetitiveness | 5nm |

| Probe size | 13×13×4.3mm^3 |

2) Sensor controller (signal processing)

E75 series single channel, small volume sensing controller

The E75 series single channel sensing controller adopts a single channel design, with a streamlined and compact structure. Its small size allows it to flexibly adapt to various scenarios with limited space. It can be adapted to various models of capacitance micrometers and is widely used in single point small displacement measurement, closed-loop control of small piezoelectric positioning systems, and other scenarios, providing efficient and accurate solutions for the high-precision sensing needs of single channels.

E01 series modular, multi-channel sensing controller

The E01 chassis type sensing controller is compatible with multiple models of capacitance micrometers, with nanometer level measurement resolution. It adopts a modular design concept and supports free selection of 1 to 12 channels. It can be flexibly combined according to actual needs and is suitable for multiple scenarios. At the same time, it provides two forms of options: desktop structure and board card plug-in, balancing the convenience of independent use and the compatibility of system integration.

For more details, please call Xin tomorrow!