-

E-mail

info@coremorrow.com

-

Phone

17051647888

-

Address

1st Floor, Building I2, Entrepreneurship Incubation Industrial Park, No. 191 Xuefu Road, Nangang District, Harbin City, Heilongjiang Province

Harbin Xinmei Technology Co., Ltd

In the fields of modern life sciences and medical research, precise manipulation within cells has become an indispensable technological means. Whether it is genetic engineering, assisted reproductive technology, or new drug development, precise manipulation of cells at the nanoscale is required. And this high-precision requirement is precisely the stage for piezoelectric nanotechnology to showcase its capabilities. Piezoelectric nanotechnology plays a crucial role in precise and controllable manipulation within cells, while ensuring their integrity and activity.

1Cell puncture and membrane rupture techniques

Cells are the basic units of life, and the cell membrane is like a delicate protective membrane - it can protect the stability of the internal environment of cells and prevent foreign substances from entering freely. But in scientific research, we often need to break through this membrane, such as delivering drugs to cells, introducing gene editing tools, or extracting substances inside cells. At this point, techniques such as cell puncture and membrane rupture are needed to break down cellular defenses.

For example, in the complete process of artificial insemination, cell puncture is the core operation that runs through key links, and its accuracy and stability directly determine the efficiency and final results of the entire process. In the process of combining sperm and egg, the positioning, angle control, and penetration force of cell puncture need to be strictly controlled, and the overall operation can be called a nanometer level fine process.

The working principle of the cell membrane disruptor is to use high-frequency vibration to achieve the effect of breaking the cell membrane. When high-frequency ultrasonic waves propagate in liquid media, they will generate local small bubbles, which will release strong energy during rapid expansion and rupture. And this energy can instantly destroy the cell wall and membrane, ultimately achieving the goal of cell membrane rupture.

Cell puncture:

Using ultra-fine needles (such as glass microneedles and nanotubes) to accurately penetrate the cell membrane, material delivery or extraction can be completed without severely damaging the cells.

Cell membrane rupture:

By using physical, chemical, or biological methods to create controllable "pores" in the cell membrane (rather than completely destroying the cell), foreign substances can enter.

IIThe core of cell puncture and membrane rupture technology:

Stable, accurate, precise, and fast

In general, the thickness of the cell membrane is only about 7-10 nanometers, and the cell membrane has elasticity - a slight excessive force can cause the cell membrane to rupture; However, the force is insufficient and cannot complete the operation of infiltrating cells. This places extreme demands on the precision and accuracy of the equipment. Traditional devices often suffer from issues such as insufficient accuracy, slow response, and imprecise force control, leading to large errors and cell punctures.

In order to achieve optimal cell infiltration, cell puncture and membrane rupture instruments need to meet the following core characteristics:

1. Ultra high precision:The positioning error needs to be controlled at the nanometer level, otherwise the target position may be missed (e.g. avoiding the nucleus and only operating on the cytoplasm);

2. Quick response:Cells will produce stress responses when stimulated, and slow operation speed can lead to active repair of membrane damage, affecting the experimental results;

3. High repeatability:In the same batch of experiments, the force, speed, and frequency of each puncture or rupture must be consistent to ensure the reliability of the experimental data.

Membrane disruptor

IIITomorrow's piezoelectric nano positioning system:

Revolutionary solution for precise cell manipulation

The unique effect of piezoelectric ceramics is that they undergo small shape changes when a voltage is applied. This effect can convert electrical signals into material deformation, achieving precise control at the nanoscale. More importantly, its response speed can reach millisecond level and it can withstand high-frequency operations without fatigue——These characteristics perfectly match the core requirements of cell puncture and membrane rupture.

How to optimize the cell puncture and membrane rupture instrument using piezoelectric nano positioning system

1.Provide nanometer level positioning accuracy

Piezoelectric ceramic actuators have high resolution and can achieve nanoscale displacement accuracy, which is the key to successful cell manipulation.

2.Realize high-speed dynamic response

The reaction time of piezoelectric ceramic actuators can reach milliseconds, making the cell puncture process fast and precise

3.No magnetic field interference

The piezoelectric driving principle neither generates electromagnetic interference nor is affected by it.

4.Compact structure and high efficiency density

Piezoelectric ceramic drive forms are divided into direct drive mechanism type and amplification mechanism type. The product has a small volume, compact structure, and is easy to integrate in limited space.

Low voltage cylindrical piezoelectric actuator

The encapsulated piezoelectric ceramic actuator is highly suitable for integration, providing nanometer level resolution, a stroke of up to 190 microns, microsecond level response time, and a very compact outer shell.

feature

·Nanoscale resolution

·High closed-loop accuracy

·Displacement can reach 190 μ m

·The output can reach 25000 N

Technical Specifications

| Nominal itinerary | 8μm~190μm |

| stiffness | 5N/μm~500N/μm |

| thrust | 300N~7300N |

| Electrostatic capacity | 0.17μF~145μF |

| resonant frequency | 3kHz~40kHz |

| length | 19.2mm~199mm |

Note: The length, diameter, pins, and interfaces of piezoelectric actuators can be customized as needed.

Low voltage annular piezoelectric actuator

The center of the low-voltage annular piezoelectric actuator has a through-hole, with two transparent aperture options of 9mm and 14mm. The bottom is fixed by threads, and the top is externally threaded. The product can be customized according to the specific needs of the user.

feature

·Displacement can reach 47 μ m

·High closed-loop positioning accuracy

·The output can reach 5300N

·The central aperture can reach 14mm

Technical Specifications

| Nominal itinerary | 11μm~47μm |

| stiffness | 50N/μm~450N/μm |

| thrust | 3000N~5300N |

| Electrostatic capacity | 2.6μF~20μF |

| resonant frequency | 9kHz~30kHz |

| length | 31mm~71mm |

Note: The length, diameter, pins, and interfaces of piezoelectric actuators can be customized as needed.

Circular piezoelectric ceramic sheet/stack

The sheet-like annular piezoelectric ceramic is a ring with a standard thickness of 2mm, and the displacement of a single piece can reach 3.3 μ m. Stacked piezoelectric ceramics are used by stacking multiple piezoelectric ceramic pieces and welding them together to form a common electrode, with a freely selectable height.

Technical Specifications

| model | NAC2121~NAC2125 |

| outer diameter | 6mm~20mm |

| inner diameter | 2mm~12mm |

| high | 2mm |

| driving voltage | 200V |

| displacement | 3.3μm |

| thrust | 1060N~8450N |

| resonant frequency | >486kHz |

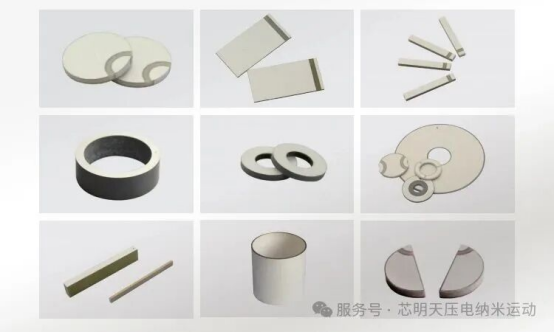

Ultrasonic piezoelectric ceramics

Materials available include PZT4, PZT5, and PZT8, which are commonly used in ultrasonic vibration, sensors, transducers, and other applications. Ultrasonic piezoelectric ceramics are mainly customized, and sizes, shapes, frequencies, electrodes, etc. can be customized according to needs.

feature

·Fast response speed

·High vibration frequency

·Sizes can be customized as desired

For more details, please call Xin tomorrow!