-

E-mail

info@coremorrow.com

-

Phone

17051647888

-

Address

1st Floor, Building I2, Entrepreneurship Incubation Industrial Park, No. 191 Xuefu Road, Nangang District, Harbin City, Heilongjiang Province

Harbin Xinmei Technology Co., Ltd

In today's era of rapid technological development, the requirements for equipment in the field of precision control are becoming increasingly stringent. From research laboratories to industrial production sites, in addition to the increasing demand for control accuracy of piezoelectric motors, the demand for fast operation of piezoelectric motors and portability of equipment is also constantly rising. The traditional controller control method is relatively single, which is difficult to meet the diverse control needs that require real-time on-site operations.

It is precisely by recognizing these industry pain points that Xin Tomorrow has launched the E53.D2E-K handheld piezoelectric motor controller, making the control of piezoelectric motors more convenient. The handheld piezoelectric motor controller can directly control the piezoelectric motor in real-time through the handle buttons, while meeting the needs of convenience, efficiency, and flexibility for piezoelectric control equipment.

1Advantages of Handheld Piezoelectric Motor Controllers

01Flexible control, adaptable to various scenarios

The E53. D2E-K handheld piezoelectric motor controller can directly control the piezoelectric motor through the handle, meeting the control requirements for quick operation and adjustment scenarios on site.

02Multi interface, smooth communication

The E53.D2E-K handheld piezoelectric motor controller can achieve real-time communication with the upper computer through USB interface or RS-232/422 interface, and supports secondary development of upper computer software. During use, the device can expand its functions according to its own needs, ensuring seamless integration with other systems and stable and reliable communication.

03Compact and portable, saving space costs

The E53.D2E-K handheld piezoelectric motor controller adopts a compact integrated design, with a size of only 134 × 58 × 248mm ³. Compared to some large controllers, it is easy to carry and can be flexibly placed in limited space on laboratory countertops or in situations where mobile operations are required, greatly saving space costs.

04Multi channel output improves work efficiency

The number of output channels is 2, which can simultaneously drive 2 linear piezoelectric motor displacement tables. The E53.D2E-K handheld piezoelectric motor controller can simultaneously control multiple devices, significantly improving work efficiency and reducing equipment investment and operation time.

IIExplanation of joystick operation effect

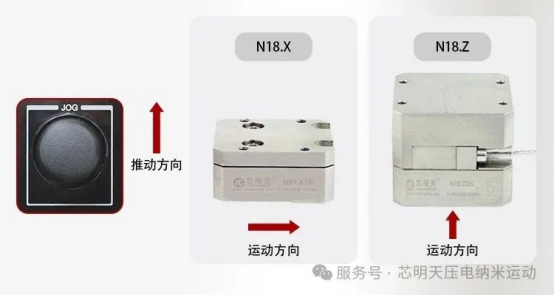

Taking the control chip tomorrow N18 piezoelectric motor displacement table as an example

1 joystick

When the joystick is pushed upwards, the piezoelectric motor immediately moves forward; When the joystick is pushed downwards, the piezoelectric motor immediately retracts; When the joystick returns to its original position, the piezoelectric motor immediately stops moving.

The joystick adopts a 9-level force sensing design, which converts the tilt angle of the joystick into a quantifiable force level. As the tilt angle of the joystick increases, the force level also increases (from level 1 to level 9), and the real-time motion speed of the piezoelectric motor will also increase linearly and synchronously. Cooperate with the SPEED indicator light to visualize the current force in real-timeLevel, lowestWhen the level is reached, all indicator lights turn off. As the intensity increases, the indicator lights gradually turn on from left to right. When the level reaches the highest level, all indicator lights turn on synchronously.

2 buttons

1) STOP button and ZERO button

When there is an emergency situation such as abnormality or misoperation during operation, simply press the STOP button to trigger the emergency braking response and stop the movement of the piezoelectric motor displacement table urgently.

Lightly press the ZERO button, and the device will trigger the zero calibration program, which can quickly control the displacement table of the piezoelectric motor to reset to the set zero reference point.

2) STEP button

Press the STEP button once, and the piezoelectric motor will move one step. Two buttons, one controls the piezoelectric motor to move forward and the other controls the piezoelectric motor to move backward.

IIIProduct Features

- 2通道

- 24VDC/2.5A (20V~30V) power supply

- Upper computer software control/controller control

- Small volume integrated design

- Closed loop servo/open-loop optional

- Drive linear piezoelectric motor displacement table/piezoelectric motor rotation table, etc

4Technical Specifications

| model | E53.D2E-K |

| servo control | Closed-loop servo control |

| number of channels | 2 |

| Power supply input voltage | 24V DC/2.5A(20~30V) |

| static power consumption | <5W |

| processor | 32bit 480MHz |

| D/A converter | 16bit |

| communication interface | TYPE-C、RS-422、RS-232 |

| Rated output power | 9W |

| Operating Temperature | 0~50℃ |

| Output short-circuit current | 60mA |

| Piezoelectric connector | DB15 |

| Communication connector | DB9、TYPE-C |

| size | 134×58×248mm³ |

| weight | 260g |

| Control method | Digital signal control/joystick control |

For more details, please call Xin tomorrow!