-

E-mail

shenyanbo@kanomax.com.cn

-

Phone

18840065038

-

Address

No. 56-39 Huanghe North Street, Huanggu District, Shenyang City

Shenyang Jiaye Scientific Instrument Co., Ltd

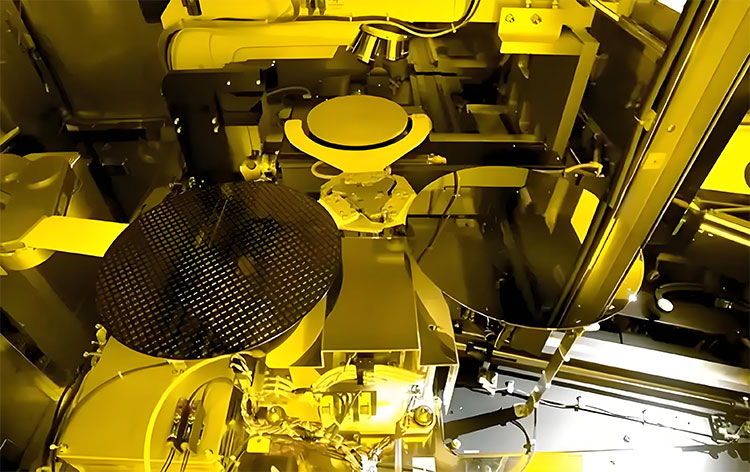

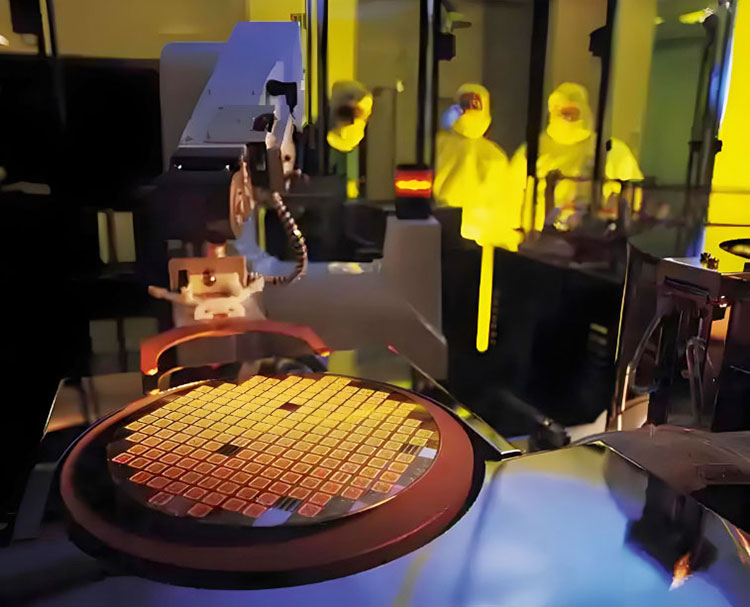

In high-precision processing industries such as semiconductor, optoelectronics, and micro/nano manufacturing, key processes such as wafer coating, development, and cleaning need to be transported and processed in an ISO Class 1 highly controlled clean environment. Any small airflow disturbance (such as local eddies, sudden changes in wind speed) or abnormal wind speed (too high or too low) during this process may cause serious problems - low wind speed can cause pollutants in the clean area to be unable to be removed in a timely manner, increasing the risk of wafer surface contamination; Excessive wind speed can easily blow the photoresist coating on the wafer surface, causing pattern deformation or defects; Airflow disturbance may also interfere with the mechanical transmission accuracy of wafers, and even cause equipment jamming faults. These problems will ultimately directly affect product yield (which may lead to a decrease of more than 10% in yield) and process stability.

Therefore, conducting precise, repeatable, and real-time wind speed monitoring inside the equipment cavity has become one of the core means to ensure process consistency, verify whether equipment performance meets standards, and identify potential risks. The environmental tester 6531 is a key equipment that meets this core requirement.

Test Process

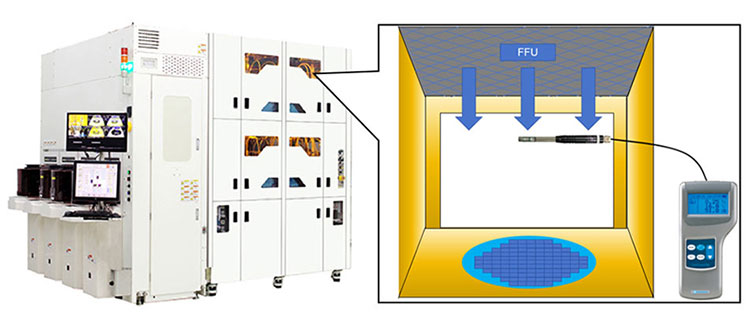

To verify whether the airflow state in the wafer transfer channel meets the process requirements, a high-precision multi parameter environmental tester 6531 is used to synchronously measure the following key parameters.

Environmental conditions:

The test needs to be conducted in a constant temperature and pressure, ISO Class 1 clean environment to avoid external particle interference in the detection. Before the test, the system needs to be self cleaned and balanced.

Wind speed range:

Coating/developing equipment (coating machine, developing machine, spraying machine)

This type of equipment requires fine operations such as photoresist coating and developer spraying during the processing. The thickness of the photoresist coating is usually measured in micrometers. If the airflow speed is too fast, it will cause defects such as ripples and edge accumulation on the coating surface. If it is too slow, it will not be able to timely remove the solvent vapor evaporated during the coating/development process, which can easily cause wafer contamination. Therefore, the wind speed needs to be strictly controlled within 0.3-1.0m/s, and it is necessary to ensure that the airflow is evenly distributed within the cross-section of the cavity.

Cleaning equipment (glue remover, single piece cleaning machine)

Chemical reagents (such as sulfuric acid, hydrofluoric acid, etc.) or high-pressure spraying are required for cleaning to remove adhesive layers and impurities, which can generate chemical vapors and particulate debris during the process. Insufficient wind speed can easily cause pollutants to adhere, resulting in incomplete cleaning; excessive wind speed can disrupt the spray water flow or cause residual reagents to quickly evaporate and form crystalline pollution. Therefore, the wind speed is set at 1.0-1.5m/s, which can efficiently remove pollutants and maintain stable airflow in the chamber without interfering with the cleaning process.

temperature and humidity:

Excessive temperature causes a decrease in the viscosity of photoresist, rapid solvent evaporation, and affects the uniformity of coating; If it is too low, the activity of the cleaning reagent will be reduced, and the cleaning effect will deteriorate; High humidity can easily cause metal corrosion and electrical short circuits in equipment, while low humidity can generate static electricity and adsorb particles to contaminate wafers. Therefore, the temperature needs to be controlled at around 25 ℃ and the humidity at around 50% RH.

pressure difference:

If the internal pressure is too low, external dusty air will seep in and pollute; If it is too high, it may cause deformation of the cavity seal and abnormal airflow, affecting the operation of the equipment. The pressure difference requirements vary for different devices: glue coating machines and developing machines have strong sealing properties and require stable airflow, with a pressure difference of usually 5-50Pa; glue removal machines and single piece cleaning machines need to accelerate the discharge of volatile gases, with a pressure difference of 50-200Pa. The overall pressure difference range is 1-200Pa (depending on the type of equipment).

test method:

1. Using grid layout method: Referring to ISO 14644-3 standard, divide the FFU air outlet surface into equal area grids of at least 3 × 3 or 4 × 4; The center of the grid is the sampling point, which also includes key areas such as below the high-efficiency filter exhaust outlet, corners of the cavity, and above the wafer transfer path. Take the average wind speed of the test section to determine if it meets the requirements.

2. Adjust the 6531 probe to face the incoming wind direction, with the measuring point 15-30cm away from the FFU air outlet surface (adjustable depending on the situation inside the equipment).

3. Adjust the 6531 probe to the center point of each grid. It is recommended to measure for at least 10 seconds each time, take multiple measurements, and record the average wind speed data.

4. End the test and perform computational analysis on the collected data records.

Attention: During testing, the equipment should maintain good sealing to avoid changing the size and direction of the FFU air flow due to poor sealing of the chamber during the testing process, which may affect the reliability of the test results.

Test effect:

Actual testing has shown that the environmental tester 6531 can accurately verify the stability of clean chamber airflow, effectively ensuring the safety and consistency of wafer transmission in the high-purity process; Meanwhile, its multi parameter synchronous monitoring and long-term data accumulation provide reliable basis for equipment debugging, acceptance, and maintenance, significantly improving production line yield and operational efficiency.

Instrument performance and application

The intelligent environment tester 65Ser can simultaneously test wind speed, air volume, temperature, humidity, and pressure. It can input the shape and size of the pipeline section to calculate the air volume. The test data retention function and statistical calculation (average, maximum, minimum) can store up to 20000 data points. There are 8 probes to choose from, and the probes are interchangeable and compatible.

The KANOMAX environmental tester 65Ser is widely used in ventilation testing, laboratory control, clean room testing, IAQ assessment, industrial hygiene, quality control, etc., to ensure process safety and product quality.