-

E-mail

sales@chotest.com

-

Phone

18928463988

-

Address

No. 1001, Xili Xueyuan Avenue, Nanshan District, Shenzhen, China

Shenzhen Zhongtu Instrument Co., Ltd

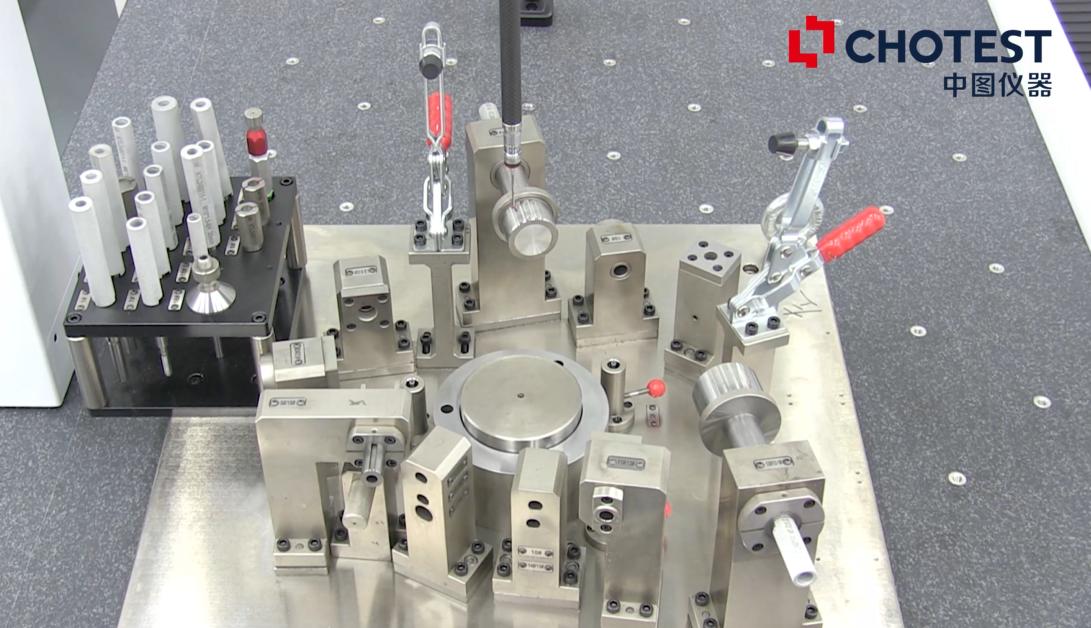

In response to the pain points in the automotive inspection industry, the Mars 8156 mobile bridge measuring machine efficiently solves key dimensions and positional tolerances of automotive inspection tools through intelligent avoidance and automatic needle changing.

1、 The entire measurement process is focused on "collision prevention"

Many engineers dare not use fully automatic mode measuring tools and prefer to manually mark points, fearing that the machine may run around and cause collisions. Mars 8156's approach to solving this problem is very straightforward: equipping the coordinate system with intelligent eyes and brains.

It is equipped with an intelligent path planning and dynamic collision avoidance system, which, with the support of Power DMIS software, can automatically identify interference areas in the digital model during the programming stage. Simply put, it means installing navigation on the machine. When the measuring head moves from point A to point B, it will not foolishly walk in a straight line to hit the clamp, but will automatically calculate a "middle point" to go around.

This means that you can confidently activate the fully automatic operation mode, allowing the machine to safely navigate through complex gauge structures even when unmanned at night. This not only protects expensive probe assets, but also ensures that the production pace is not interrupted.

2、 Change needles like a knife, handle ever-changing features

There are various features on the inspection tool: some deep holes require extension rods, some side holes require star shaped needles, and some grooves require small-diameter needles. If you are still relying on manual needle changing, how can efficiency be improved?

The strategy of Mars 8156 is to combine an intelligent probe extension rod with an automatic needle changing rack system. It allows machines to automatically replace different measuring needle modules based on program instructions, just like CNC machines.

In a measurement program, the machine can seamlessly switch between multiple configurations: one second it was still using a 50mm extension rod to measure deep holes, and the next second it automatically switched to using a star shaped needle to measure the side wall slot. The entire process does not require manual intervention, and the switching time only takes a few seconds. This strategy truly implements the concept of "one machine for multiple uses", which not only significantly reduces downtime waiting time, but more importantly, it eliminates the repetitive errors caused by manual disassembly and ensures the authenticity of every key dimension data on the gauge.

3、 Can withstand the turbulence of the workshop environment

The measurement of gauges is often not conducted in a constant temperature laboratory, but in a quality inspection room near the production line, where environmental vibrations and temperature fluctuations are normal. That's also why many delicate machines encounter various problems as soon as they enter the workshop.

Mars 8156 adopts a classic mobile bridge structure, which combines high-performance air bearing guide rails and grating ruler system to balance "rigidity" and "flexibility". It can ensure dynamic stability during high-speed operation (without shaking during emergency stop and start), and resist temperature interference in the workshop environment through excellent material thermal stability.

For engineers, whether you are measuring positional and profile tolerances (GD&T) or performing complex RPS coordinate system fitting, this machine can provide high-precision data with traceability.

In summary, when it comes to the efficiency of car inspection tool acceptance, Mars 8156 understands safety (intelligent avoidance), efficiency (automatic needle changing), and accuracy. If you are still worried about the efficiency and safety of measuring tools, this equipment may be the puzzle for upgrading your production line.