-

E-mail

sales@chotest.com

-

Phone

18928463988

-

Address

No. 1001, Xili Xueyuan Avenue, Nanshan District, Shenzhen, China

Shenzhen Zhongtu Instrument Co., Ltd

In the selection process of a coordinate measuring machine (CMM), the most fundamental and critical decision often occurs at the architecture level: whether to choose the mainstream moving bridge or the massive gantry?

This is not only about the difference in measurement volume size, but also about the underlying logic of dynamic performance, structural rigidity, and measurement uncertainty. For metrology engineers, understanding the mechanical principles behind these two is a prerequisite for making a correct ROI (return on investment) assessment.

1、 Mobile Bridge: Measuring the Stability of Small and Medium sized Workpieces

The mobile bridge structure currently holds over 80% of the CMM market share. Its core features are: the workbench is fixed, the bridge (Y-axis) moves along the guide rail, and the X/Z-axis sliding plate moves on the bridge.

For small and medium-sized manufacturing enterprises, the mobile bridge coordinate measuring machine can achieve a balance between accuracy and production capacity at a lower overall cost (reducing equipment footprint by 30% and energy consumption by 15%).

2、 Gantry: a deformation control scheme for large workpieces

When upgrading the measurement object to a whole vehicle body, aviation structural components, or wind turbine blades, choosing a gantry structure coordinate measuring machine is appropriate. Its core feature is that the Z-axis skateboard moves along the elevated crossbeam, which is mounted on fixed columns (or concrete walls) on both sides. The workbench is open, even borrowing the floor directly.

The Longmen coordinate system mainly solves the problems of self weight deformation and vibration interference of heavy-duty and large-span workpieces. For ultra large workpieces such as heavy machinery and new energy battery packs, the gantry type coordinate measuring machine has the advantages of large measurement range and large span rigidity, which can ensure accuracy stability within a 20-year life cycle.

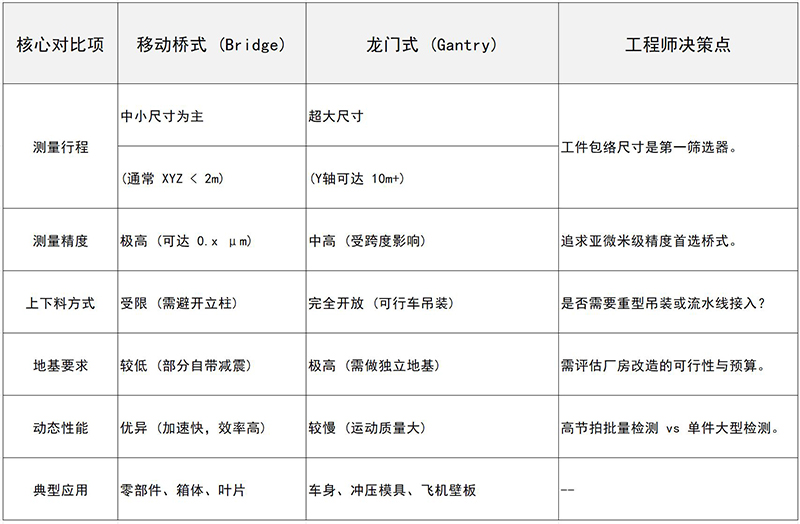

3、 Decision reference: Comparison of technical parameters

4、 Selection suggestions

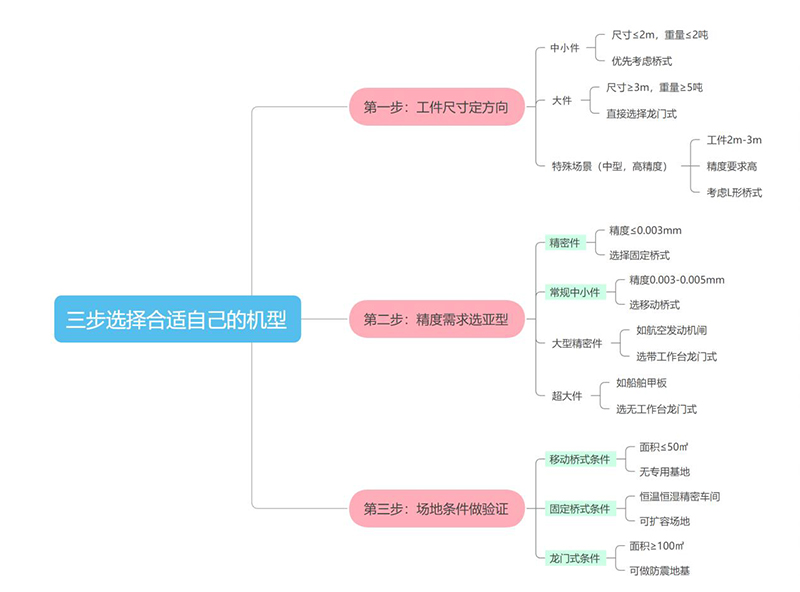

Based on industry practice, manufacturing enterprises can quickly complete the selection and judgment of bridge and gantry types through the three-step method of 'workpiece characteristics → precision requirements → site conditions'.

Three steps to choose the appropriate CMM model mind map

In general, under the current demand for high-precision and large-sized measurement in the manufacturing industry, bridge CMM is still the choice for micrometer level small parts, while gantry CMM is the measurement platform for large and heavy parts. So when choosing a three coordinate system, we need to evaluate it based on the three dimensions of "measurement volume x x accuracy x speed". We need to consider our own production line layout and budget in order to select the model that suits our measurement needs.

The essence of selection is not to pursue parameters, but to achieve scene adaptation.