-

E-mail

sales@chotest.com

-

Phone

18928463988

-

Address

No. 1001, Xili Xueyuan Avenue, Nanshan District, Shenzhen, China

Shenzhen Zhongtu Instrument Co., Ltd

In industrial fields such as microelectronics manufacturing, photolithography technology, and aerospace, accuracy is the core key to determining the success or failure of products. Accuracy deviations below millimeters often mean the scrapping of the entire batch of products, equipment downtime, and even project delays.

1、 Industry pain points

Traditional position feedback devices such as steel tape rulers or glass gratings are limited by material thermal expansion, installation errors, and environmental interference, making it difficult to meet the high requirements for stability, resolution, and anti-interference ability in current ultra precision machining

One is that the measurement accuracy cannot meet the requirements of nanoscale processing, resulting in a sharp drop in product yield;

Secondly, the poor adaptability of measuring equipment to the production environment, as well as limitations in host heat dissipation and installation space, affect measurement stability;

Thirdly, in multi degree of freedom measurement scenarios, traditional equipment is difficult to balance efficiency and accuracy, which slows down the production pace.

These are not only technical issues, but also systemic challenges that affect yield, production efficiency, and equipment reliability, and fiber laser rulers are precisely high-precision measurement solutions designed to address these industry pain points.

2、 Fiber laser ruler: system level precision solution

The PLR3000 fiber laser ruler is based on the principle of laser interference, transmitting helium neon laser through a polarization maintaining fiber to the interference probe, with a frequency stabilization accuracy of up to 0.02ppm - which means that the frequency fluctuation error is only 0.02 micrometers at a measurement distance of 1 meter, far superior to traditional measurement tools. Realized non-contact, high-resolution, multi-channel position feedback. At the same time, its linear measurement accuracy reaches 0.2~0.5ppm. Taking the PLR3200 PRO model with 0.2ppm as an example, the maximum error when measuring a 4-meter range is only 0.8 microns, which meets the nanometer level accuracy requirements for wafer positioning in chip lithography.

More importantly, the equipment adopts a design that separates the laser emitting device from the interference probe, and is connected by a 3-meter armored optical fiber. This not only keeps the host away from the heat source of the production line, avoiding interference from temperature changes on the measurement path, but also flexibly adapts to narrow installation spaces, reduces Abbe errors, and solves the dilemma of "accuracy and environmental adaptation".

But its core value lies not in measurement, but in building a stable and reliable position reference system.

3、 Key technological advantages

1. 0.02ppm frequency stability accuracy: eliminate frequency drift from the source to ensure long-term stability;

2. 10nm resolution: supports motion control at the micrometer or even sub micrometer level;

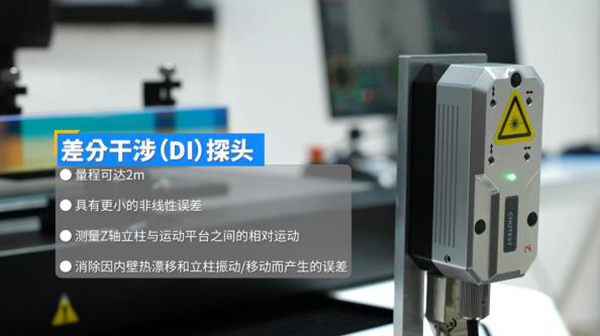

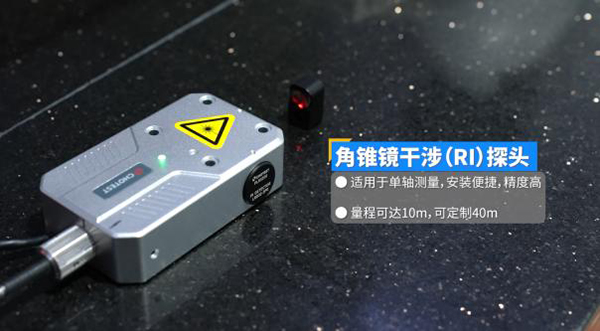

3. Multi probe configuration: supports various optical structures such as corner prisms, plane mirrors, differential interferometry, etc., suitable for different scenarios such as mirrors, linear axes, rotating tables, etc;

4. Environmental compensation unit: Real time monitoring of temperature, humidity, and air pressure, automatically correcting the influence of air refractive index to ensure the authenticity and reliability of measurement data;

5. Host and probe separation design: Through armored fiber optic connection, the laser can be kept away from heat and vibration sources, reducing system interference.

4、 Typical application scenarios and solution value

Scenario 1: Multi degree of freedom positioning of lithography machine workbench

Three axis synchronous output, combined with differential interferometer, can achieve nanometer level closed-loop control of the workbench, improving the accuracy of engraving and equipment throughput.

Scenario 2: Precision Machine Tool Tool Tool Compensation and Feedback Control

By installing a planar mirror interferometer and providing real-time feedback on the blade position, combined with environmental compensation function, a linear accuracy of ± 0.5ppm can be maintained even in environments with large temperature fluctuations in the workshop.

Scenario 3: Aerospace field

When processing large components, it is necessary to consider both long-distance and multi degree of freedom measurements. Choosing a conical prism interference probe (with a maximum range of 4m and a maximum speed of 2m/s), combined with an integrated environmental compensation unit, can automatically monitor temperature, air pressure, humidity, and real-time correct the laser refractive index. Even under fluctuations in the vehicle environment, it can ensure measurement accuracy

With the deepening of Industry 4.0 and intelligent manufacturing, measurement technology also needs to be upgraded synchronously. The fiber laser ruler not only meets the current nanoscale measurement needs, but also has scalability - the PLR3000 range can exceed 4m, and the resolution can be further improved through external expansion, leaving space for higher precision manufacturing scenarios in the future. At the same time, its multi-channel output and customized probe design can be deeply integrated with automated production lines, helping enterprises achieve closed-loop control of "measurement feedback adjustment" and promoting the transformation of manufacturing processes towards intelligence. For manufacturing enterprises facing precision bottlenecks, choosing appropriate measurement tools is a crucial step in breakthrough development.