-

E-mail

cubic-ry56@gasanalyzer.com.cn

-

Phone

18627990650

-

Address

No. 6 Fenghuangyuan Middle Road, Fenghuangyuan Industrial Park, Donghu New Technology Development Zone, Wuhan City, Hubei Province

Sifang Optoelectronics (Wuhan) Instrument Co., Ltd

Monitoring the gas composition of the Lurgi furnace is the cornerstone of efficiency and safety

In coal based gas production technology, fixed bed, fluidized bed, fluidized bed and other processes have their own characteristics. Among them, the Lurgi pressurized gasification method, as one of the oldest fixed bed pressurized gasification processes in history, continues to play an important role in the fields of coal to natural gas (SNG), urban gas, and chemical synthesis gas due to its unique advantages of coal crushing counter current gasification, high by-product tar and methane content. However, its complex reaction process and diverse product composition require real-time and accurate monitoring of gas composition. Mastering key gas component data is the core prerequisite for optimizing process operations, ensuring safe production, and improving economic benefits.

The core pain points of gas monitoring

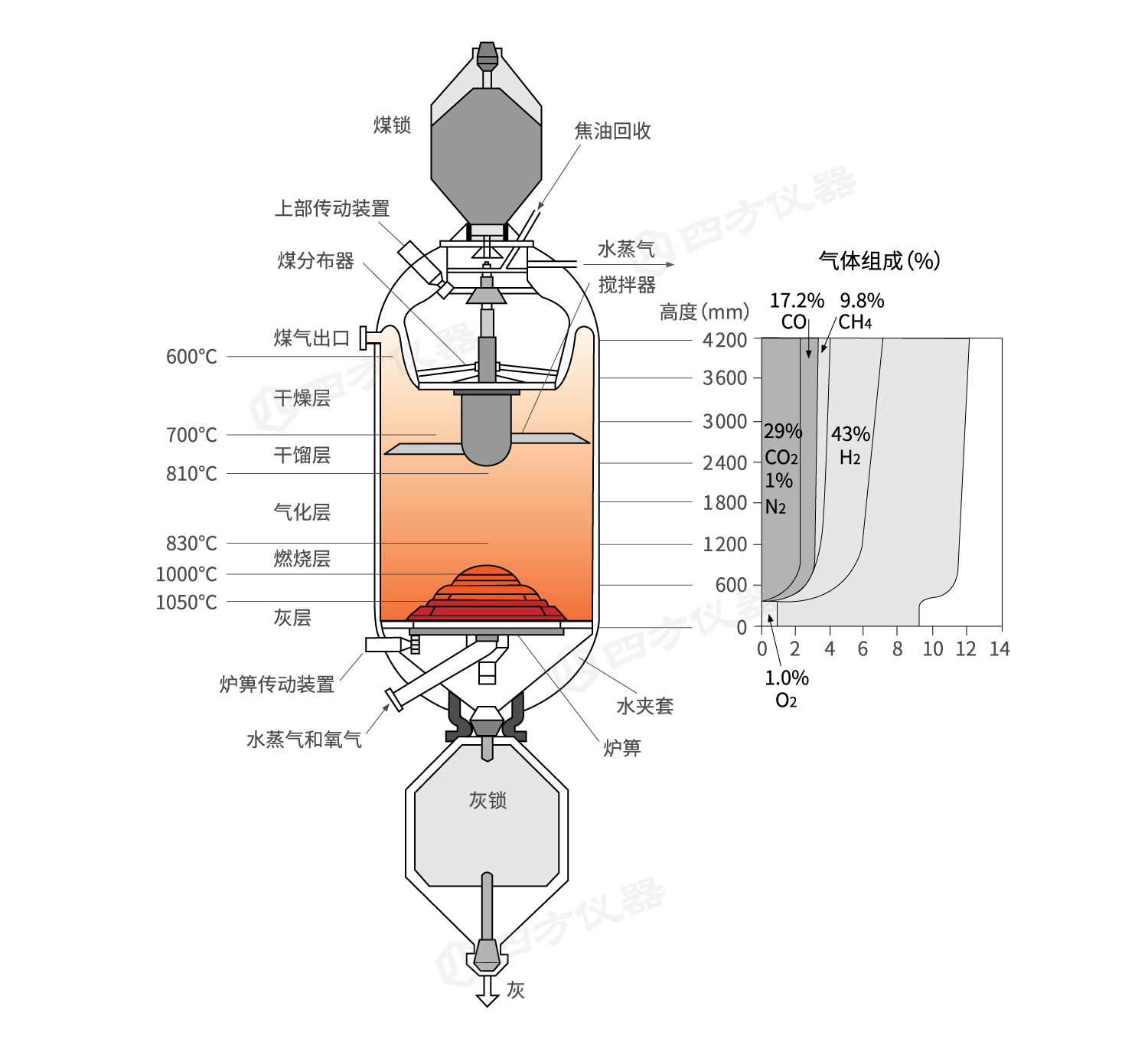

1. Process description:

Crushed coal is added from the top of the furnace, and the gasifying agent (oxygen+steam) flows upstream from the bottom of the furnace. The coal material undergoes a complete reaction chain from dehydration pyrolysis to deep gasification in the furnace: drying and dry distillation are completed in the low-temperature zone at the top, and volatile matter is released; Gasification reaction occurs in the central high-temperature zone, generating effective gases mainly composed of CO, H2, and CH4; The bottom combustion zone provides heat for gasification, ultimately forming ash residue for discharge.

This highly dynamic and heterogeneous system spanning multiple temperature zones and reaction types not only has a complex reaction process, but also has diverse product compositions. In addition to the target product CH4, it also accompanies various components such as heavy hydrocarbons, tar, phenols, ammonia, sulfides, etc. In addition, the harsh working conditions of high temperature, high pressure, high dust, and high tar make real-time and accurate monitoring of key gas components (such as CO, H2, CH4, CO2, O2, and other pollutants) a core challenge for optimizing process efficiency, ensuring safe operation, and improving economic benefits.

2. The significance of monitoring key reaction processes:

• C+H2O →CO+H2

As the main endothermic gasification reaction, the concentration of its products H2 and CO directly reflects the gasification efficiency and is the core indicator for process monitoring.

• C+2H2 →CH4

This exothermic reaction is a characteristic pathway for the production of high calorific value CH4 in the Lurgi furnace, therefore monitoring CH4 concentration becomes a key basis for evaluating the economic output of the device.

• CO+H2O → CO2+H2

This reversible water gas shift reaction profoundly affects gas composition, and real-time monitoring of the concentrations of CO, CO2, and H2 and paying attention to their ratios is crucial for understanding reaction equilibrium and optimizing processes.

3. Monitoring difficulties:

The demand for whole component analysis is urgent: the composition of crude coal gas is extremely complex, including H2, CO, CO2, CH4, N2, O2 (trace) H2S、NH3, And tar vapor, dust, etc. It is necessary to simultaneously and quickly obtain the concentration of key components to comprehensively evaluate gasification status, calorific value, process efficiency, and safety risks. Traditional analytical methods have limitations, such as long chromatographic detection cycles, inability of Fourier transform infrared to detect diatomic molecules such as H2, N2, O2, and severe cross interference.

• Methane and effective gas yield: It is necessary to accurately and quickly monitor the concentration of CH4 and higher-order hydrocarbons CnHm in crude gas and accurately determine their calorific value, which is an important manifestation of the economic value of the Lurgi furnace. Meanwhile, the concentration of effective gases such as H2 and CO is also an optimization target.

The severe challenge of complex and harsh working conditions: Continuous operation in environments with high temperature, high pressure, high tar, high dust, and corrosive gases (such as H2S) can easily lead to sampling system blockage and equipment corrosion failure; Optical measurement window contamination, signal attenuation and distortion; The traditional preprocessing system results in frequent maintenance and low reliability.

Real time monitoring of security risks: The trace amount of O2 remaining in the system replacement is a potential explosion hazard; Toxic and harmful gases such as H2S and COS pose a threat to personnel health and equipment safety, requiring highly sensitive, stable, and reliable monitoring.

Key gas concentration monitoring points and core requirements

1. Crude gas outlet (core point):

Monitoring components: H2、N2、O2、CO、CO2、H2S、NO、CH4、C2H2、C2H4、C2H6、C3H6、C3H8、i-C4H8、n-C4H8、i-C4H10、n-C4H10 Waiting for full component analysis.

Requirements: Multi component synchronous online measurement, fast response, high-precision resistance to tar/dust/water vapor interference, high temperature and high pressure corrosion resistance, low maintenance. This point data is the core basis for process control, efficiency calculation (calorific value, methane yield, carbon conversion rate), and safety monitoring.

2. Wash cooling tower outlet/purified gas inlet:

Monitoring components: CO, CO2, CH4, H2S, H2, O2, N2, etc.

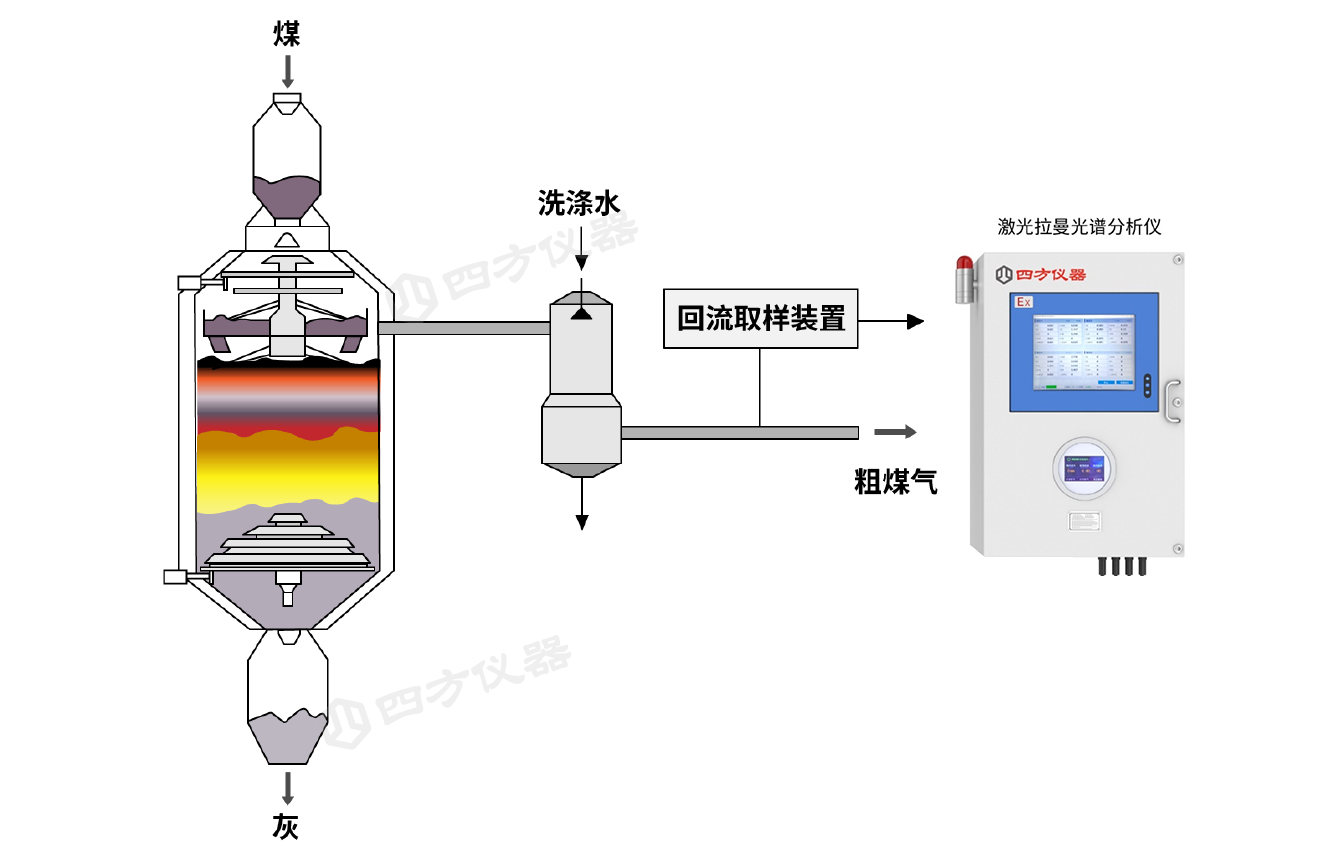

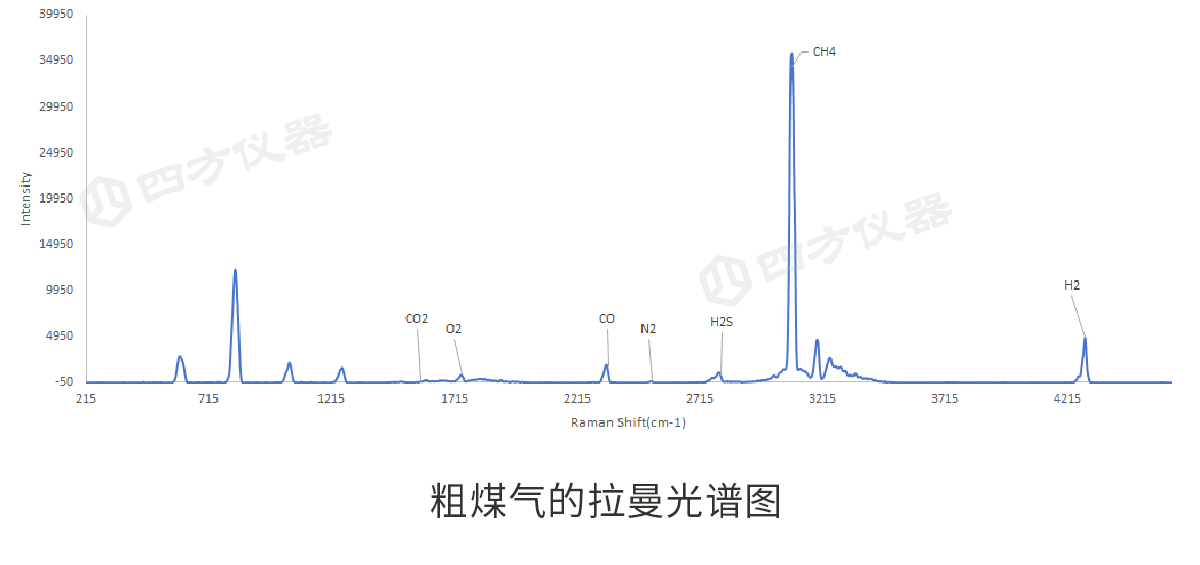

Requirement: The gas here is relatively clean, but stable and reliable monitoring of multi-component or key component concentrations is still required to evaluate the washing and purification effects and control downstream sections. As shown in the figure below, the Raman spectra of CO, CO2, CH4, H2S, H2, O2, and N2 components obtained by LRGA-3200EX from Raman spectroscopic scanning analysis of the crude gas sample at the outlet of the coal gasification unit washing tower have distinct characteristic peaks. By measuring the characteristic peak height, the content of each component gas can be determined simultaneously.

Breakthrough in Difficulty: In Situ Analysis Advantages of Four party Instrument Raman Scheme

In the face of the complex composition and harsh working conditions of the raw gas outlet from the Lurgi furnace, in-situ analysis technology has demonstrated irreplaceable advantages in key monitoring needs. The core solution recommended by Sifang Instrument is the in-situ laser Raman spectroscopy gas analyzer LRGA-3200EX.

Technical principle description: Raman spectroscopy is based on the inelastic scattering generated by the interaction between light and molecules. Different molecules have unique "fingerprint" Raman shift spectra, and a single instrument can simultaneously identify and quantify multiple gas components.

Overcoming core difficulties:

•Multi component synchronous rapid analysis, one machine controls the whole situation:A single device can synchronously measure multiple key components (including homonuclear diatomic molecules H2, O2, N2, as well as CH4, CO, CO2, H2S, COS, CnHm, etc.) in crude gas in real-time online, with a response speed of seconds. No need for complex preprocessing, no cross interference, providing the most direct real-time full component data of process gases. Equipped with 4-channel synchronous measurement capability as standard, it easily meets the needs of multi-point parallel monitoring.

•Gas concentration and calorific value are displayed synchronously, with zero delay in decision-making:During the production process, the gas composition and calorific value are constantly changing dynamically. The Raman analyzer of the four party instrument accurately monitors the concentration of each component, calculates and synchronously displays the calorific value in real time, eliminates data lag, and provides timely and accurate basis for optimizing process parameters.

•Fearless of harsh working conditions, high fidelity of in-situ measurement:The core advantage lies in the design of in-situ probes that are resistant to high temperature, high pressure, and corrosion. The probe is directly inserted into the process pipeline to obtain concentration information in situ and transmit it back at high speed through a long optical fiber, effectively avoiding pain points such as component distortion, adsorption, condensation, tar blockage, and frequent maintenance caused by sample gas transmission in the extraction method.

•Double security guarantee, escorting production and personnel:High precision monitoring of trace O2, early warning of explosion risks; Real time locking of toxic gas concentrations such as H2S and COS to ensure personnel safety. The instrument body adopts a positive pressure explosion-proof design and is equipped with customizable length optical fibers of ≥ 50 meters, ensuring that the analysis unit is always far away from high-risk process areas and achieving intrinsic safety.

More technical solutions to choose from:

Non dispersive infrared gas analyzer (NDIR technology):The Gasboard-3500 has high-precision online monitoring capabilities for ultra-low concentration CO/CO2 ranging from 0 to 100ppm, and can accurately measure key parameters such as CH4 and calorific value. Equipped with a professional pre-processing system to ensure stable operation under harsh conditions such as high humidity and high dust, the explosion-proof design provides industrial safety protection.

Extraction based laser gas analysis system (TDLAS technology):GasTDL-3110 is designed for working conditions with high dust content in the sample gas. It consists of four parts: sampling probe, preprocessing unit, control unit, and gas analysis unit, which can continuously reflect the concentration of the measured gas in real time.

Conclusion

The complex gas composition and harsh working conditions of the Lurgi furnace process make reliable, accurate, and comprehensive in-situ gas composition monitoring the lifeblood of its efficient and safe operation. The laser Raman spectroscopy gas analysis technology independently developed by Sifang Instrument, with its core advantages of anti-interference ability, tolerance to harsh working conditions, and low maintenance of multi-component synchronous in-situ measurement, has successfully solved the key challenges of gas monitoring in Luqi furnace, providing customers with powerful data support for process insight, optimized operation, and safety assurance. Choose Sifang to endow your Lurgi furnace device with precise and reliable "eyes of craftsmanship" and "shields of safety".