-

E-mail

cubic-ry56@gasanalyzer.com.cn

-

Phone

18627990650

-

Address

No. 6 Fenghuangyuan Middle Road, Fenghuangyuan Industrial Park, Donghu New Technology Development Zone, Wuhan City, Hubei Province

Sifang Optoelectronics (Wuhan) Instrument Co., Ltd

Project Background

Cooperation Background

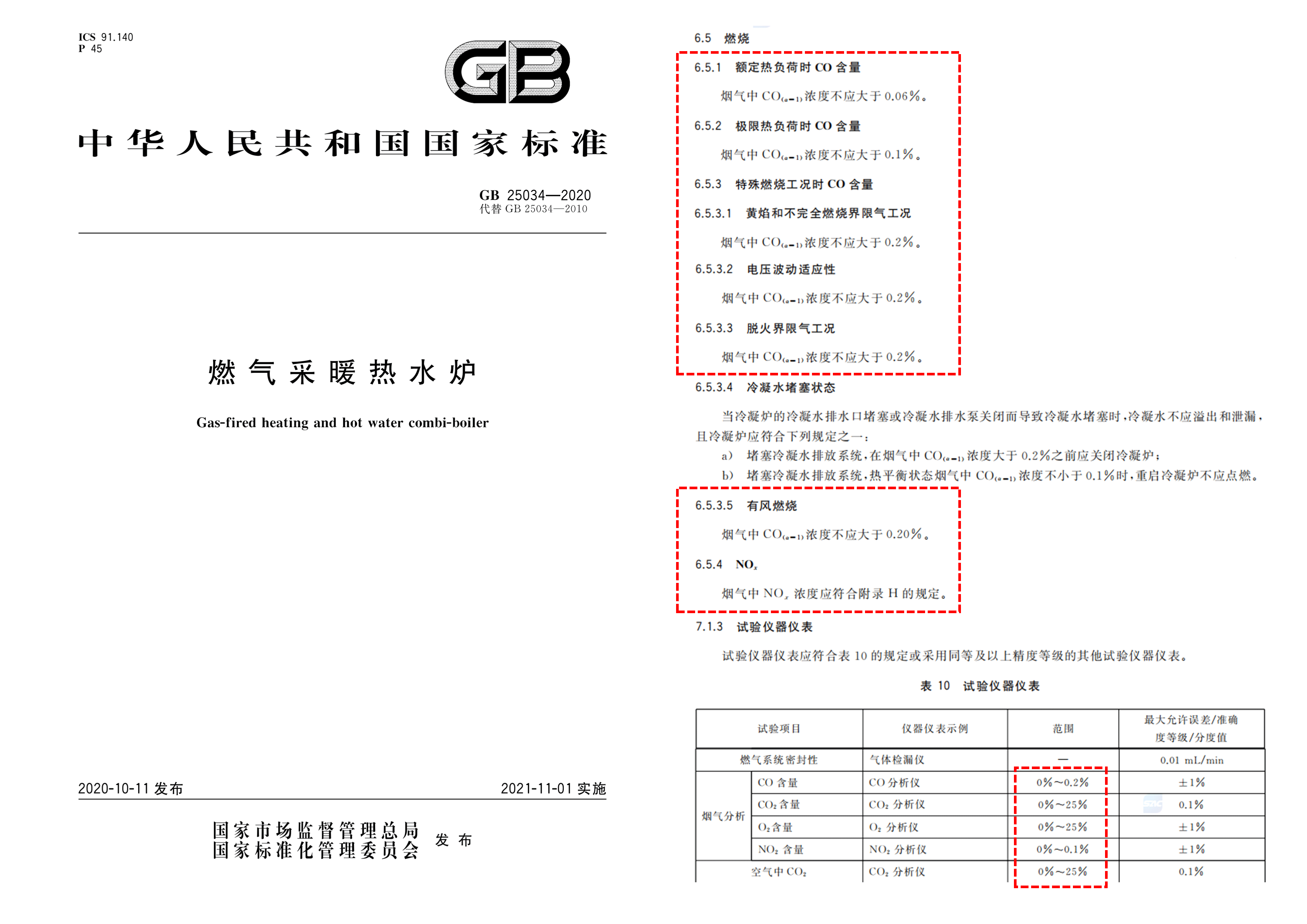

Currently, the gas heating and hot water boiler industry is moving towards higher energy efficiency and lower emissionsAnd more reliable and secureThe direction continues to develop. The national mandatory standard GB 25034-2020 "Gas Heating Water Heater" sets clear and strict requirements for various emission indicators, especially the limits of carbon monoxide (CO) and nitrogen oxides (NOx). For enterprises that value long-term development, meeting standards is only the foundation, and they need to establish advantages in competition,Optimize combustion controlTo pursue a higher level of environmental protection, it is necessary toworkmanshipQuality control fromback-endReal time monitoring and dynamic optimization of the combustion process before detection. Therefore, real-time and accurate online monitoring of combustion process gases (including O2, CO2, CO, and NOx) has become a common practiceIndustry leadersThe inherent need for enterprises to enhance the core competitiveness of their products.

Project Introduction

The user of this project is a comprehensive thermal energy solution provider, whose main business covers the research and development, manufacturing, and service of products such as gas wall mounted boilers and heat pumps. The company has a laboratory accredited by CNAS and has been deeply involved in the preparation and revision of multiple national and industry standards, with extremely strict control over product quality.

In order to continuously improve technical strength and analysis efficiency, the customer plans to upgrade its core gas analysis system, aiming to introduce a domestically produced online gas analysis solution that is more responsive and has comprehensive advantages, mainly applied in the following three scenarios:

1. Laboratory research and process adjustment: As the primary requirement, when debugging the core parameters of the burner (such as air-fuel ratio) in the laboratory, it is required that the gas analysis instrument can reflect the instantaneous changes in flue gas concentration after parameter adjustment in real time and accurately, providing real-time data support for engineers to optimize process design.

2. Laboratory Sampling Performance Verification and Rating: In the laboratory, strict sampling and testing of combustion process gases are conducted to verify the combustion efficiency, emission levels, and safety functions of products under different operating conditions. Among them, the monitoring data of NOx (NO, NO2) will be specifically used for the environmental rating assessment of products, providing key data basis for their entry into the market.

3. Rapid screening of production line terminals: At the end of the final assembly line, a rapid ventilation inspection is carried out on each product that is about to leave the factory to confirm whether its basic combustion state has quickly stabilized within the qualified range after startup, achieving online rapid quality inspection and control of all products.

Product Prototype

Online gas analysis system

Main parameters

Measure components |

CO、CO2、O2、NO、NO2 |

analytical method |

NDIR:CO、CO2 Paramagnetic: O2 UV-DOAS:NO、NO2 |

range |

CO:0~3000 ppm; CO2:0~25%; O2:0~25%; NO/NO2:0~200ppm |

repetitiveness |

CO/CO2:≤1%F.S. O2/NO/NO2:≤2%F.S. |

response time |

≤3s(NDIR); ≤15s(顺磁); ≤30s(UV-DOAS) |

Operating temperature |

0~50 ℃, relative humidity 95% RH |

sampling flow |

0.7~1.2L/min |

analog output |

4-20mA output RS-485/232 |

project implementation

Technical Solution

The core requirement of the customer is that the analyzer not only needs to monitor the final emission gas, but also needs to deeply reflect the state of the combustion process and meet the full standard detection requirements. For this purpose, our company's online gas analysis solution integrates technologies such as paramagnetic, non dispersive infrared (NDIR), and ultraviolet differential spectroscopy (UV-DOAS), which can simultaneously and continuously measure the concentrations of O2, CO2, CO, as well as NO and NO2.

1. Multi parameter synchronous monitoring, comprehensive insight into combustion and emissions

Unlike monitoring only a single emission, this scheme directly obtains the core parameters of the combustion process by synchronously measuring the concentrations of O2 and CO2. The O2 concentration is used to accurately calculate the real-time excess air coefficient, while the CO2 concentration directly characterizes the degree of combustion. By combining real-time concentrations of CO and NOx, engineers can comprehensively evaluate combustion efficiency, safety margins, and environmental performance, thereby optimizing combustion from the source, ensuring that products fully meet standards and have high-level competitiveness.

2. Millisecond level dynamic data, matching debugging rhythm

The core advantage of this solution lies in its extremely fast response speed and millisecond level data jump updates. When changing combustion conditions, simulating voltage or pressure fluctuations, etc. during laboratory debugging, the system can capture and present the dynamic changes in O2, CO2, CO, and NOx concentrations in real time. This real-time feedback can help engineers more intuitively judge the instantaneous impact of each adjustment on combustion conditions and emission levels, quickly locate parameter combinations, and greatly improve the efficiency and accuracy of research and development debugging.

3. The comprehensive monitoring capability meets strict standards and level evaluations

The monitoring accuracy of the instrument for CO reaches the ppm level, meeting the strict limit requirements of as low as 0.06% (600 ppm) in the national standard. Meanwhile, the measurement accuracy and stability of the NOx (NO, NO2) monitoring module in the scheme meet the limit requirements for nitrogen oxides in GB 25034-2020. The high reliability of the entire system meets the metrological management requirements of CNAS laboratory for testing equipment, providing complete data support for the routine performance verification and grading of products.

Solution Value

The implementation of this plan provides direct and in-depth value for key business processes of customers:

Accelerating the R&D innovation cycle: providing real-time data analysis for laboratory process debugging, transforming the traditional "test wait analysis" mode into an efficient process of "real-time adjustment real-time verification", significantly shortening the R&D and finalization time for new products and models.

Strengthen quality and environmental protection levels: achieve online rapid screening of all products at the production end, effectively intercepting basic process fluctuations; In the laboratory, not only can routine performance verification be completed, but NOx data can also be accurately obtained, providing strong evidence for product environmental rating assessment and building a dual quality guarantee of coverage performance and environmental protection.

Realizing reliable and high-performance domestic substitution: The successful application of this system, especially in comparison with the original imported equipment, demonstrates comparable or even better real-time performance and stability, proving that high-quality domestic solutions can meet the requirements of the manufacturing industry for core detection equipment in the field of gas analysis, forming a reliable substitution example.

In this cooperation, Sifang Instrument has built a closed-loop data chain for customers from the research and development source to the factory terminal, from basic performance to environmental rating reference, transforming precise gas analysis capabilities into core driving forces for product performance improvement, market access, and competitiveness enhancement.

project site