-

E-mail

sales@chotest.com

-

Phone

18928463988

-

Address

No. 1001, Xili Xueyuan Avenue, Nanshan District, Shenzhen, China

Shenzhen Zhongtu Instrument Co., Ltd

1、 What is an image measuring instrument?

In the field of precision manufacturing, from the tiny pins of electronic components to the complex surfaces of automotive parts, dimensional accuracy directly determines whether the product can be assembled and run stably. But many companies always encounter various difficulties when measuring: using traditional calipers to measure small parts, if not careful, the workpiece may be crushed due to improper force; Manually comparing drawings and recording data is not only time-consuming, but also often leads to a deviation of ± 0.003mm due to visual errors, which can cause chain problems in subsequent production.

And the image measuring instrument is a non-contact precision measuring device designed to solve these problems. It captures workpiece images through high-resolution industrial cameras, and then uses dedicated image processing algorithms to accurately identify workpiece edges and contours, quickly calculating key parameters such as length, angle, roundness, etc. Without direct contact with the workpiece, it can avoid damaging vulnerable parts and break through the measurement limitations of traditional tools, making precision measurement more efficient and accurate.

2、 The core functions of an image measuring instrument

The functional advantages of image measuring instruments are built on a solid technological foundation, and each item accurately corresponds to the actual measurement needs of the enterprise.

1. Ultra high precision measurement function

It is equipped with a high-precision grating ruler, with a minimum reading of 0.1 μ m. Combined with a 5-megapixel industrial camera, it can accurately capture even small size differences of 0.001mm. For example, measuring the thickness of mobile phone screen glass, traditional tools are difficult to guarantee accuracy, while image measuring instruments can control the error within ± 0.001mm, ensuring that each piece of glass meets assembly standards.

2. Efficient batch measurement function

Traditional measurement of a part containing 8 dimensional parameters requires frequent tool changes and takes at least 15 minutes, while image measuring instruments can complete all parameter measurements in one shot, produce results within 3 minutes, and automatically generate reports with data charts.

3. Complex shape adaptation function

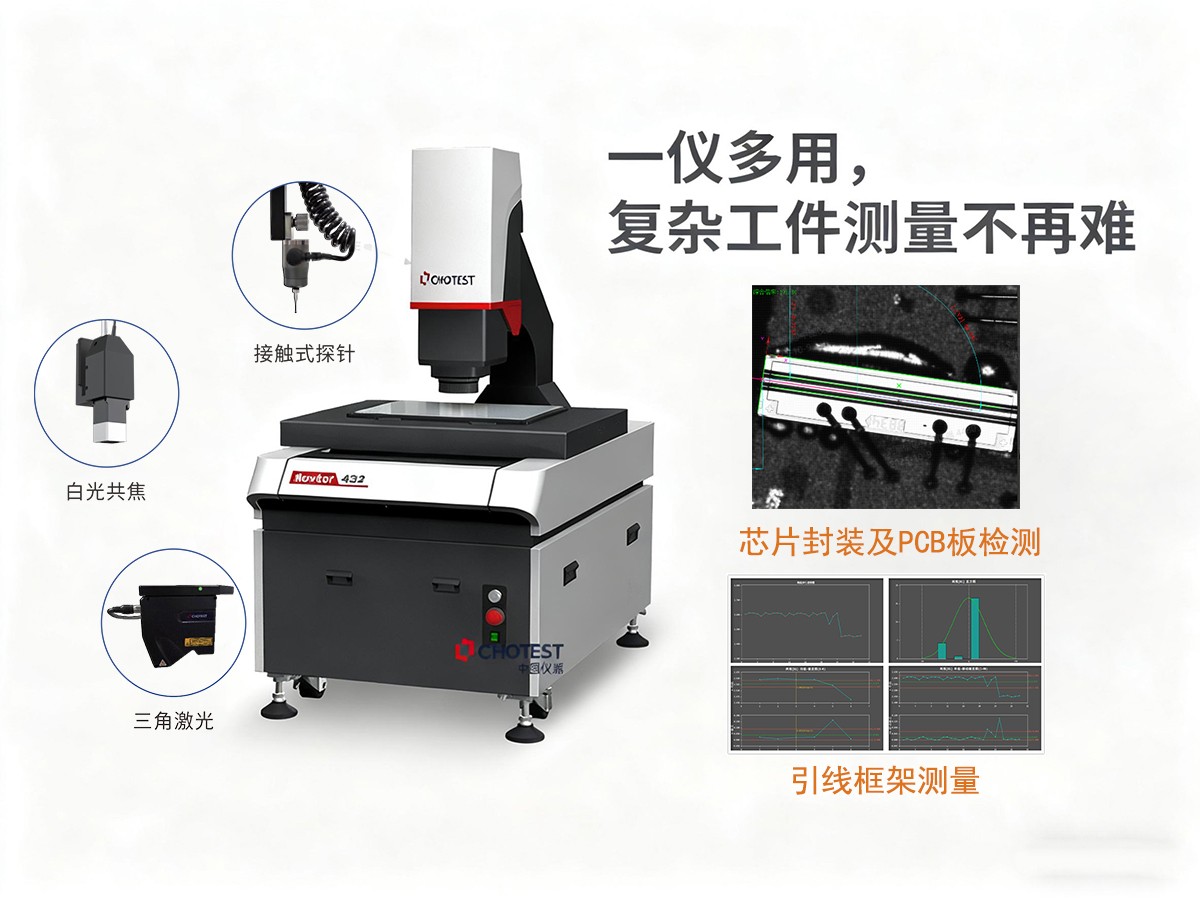

By replacing lenses with different magnifications, it can accurately measure electronic component pin spacing as small as 0.5mm and car bumper contours as large as 800mm. Faced with complex workpieces with curves and grooves, traditional tools are difficult to fully capture dimensions, while image measuring instruments can easily calculate complex parameters such as coaxiality and perpendicularity by capturing images from multiple perspectives, restoring the three-dimensional shape of the workpiece.

3、 Practical application in industry scenarios

1. Electronic component testing

(1) Measurement of PCB board pad size

(2) Pin spacing detection of connectors

(3) Profile analysis of micro components

2. Quality control of precision components

(1) Mold size verification

(2) Gear parameter measurement

(3) Complex surface contour detection

4、 How to choose an image measuring instrument

Nowadays, the manufacturing industry has increasingly high requirements for accuracy and efficiency, and traditional measurement methods are gradually unable to meet the needs. Image measuring instruments are becoming the mainstream choice for precision measurement in the industry. It can not only solve the measurement pain points of current enterprises, but its technological development is also closely in line with industry trends - in the future, with the integration of AI technology, image measuring instruments will achieve automatic recognition and measurement of workpieces, further reducing manual intervention; Combined with laser scanning technology, it can also expand 3D measurement capabilities to meet more complex measurement needs. It is recommended that companies evaluate their own needs from three dimensions:

1. Measurement accuracy requirements

2. Efficiency requirements for detection

3. Future scalability considerations

If your enterprise is facing the problems of insufficient measurement accuracy and low efficiency, it is advisable to start from actual needs, understand the specific configuration and application plan of image measuring instruments through sample testing, process analysis, and other methods, choose suitable measurement solutions, and let them assist in the precision production of the enterprise.